Prints (0)

-

No Prints Yet

Be the first to upload a Print for this Design!

Description

3D Printing is an additive manufacturing process that creates a physical object from a digital design. There are different 3D printing technologies and materials you can print with, but all are based on the same principle: a digital model is turned into a solid three-dimensional physical object by adding material layer by layer.

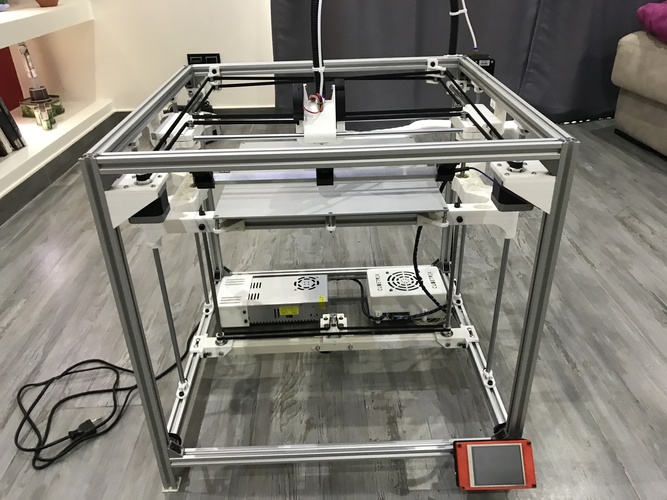

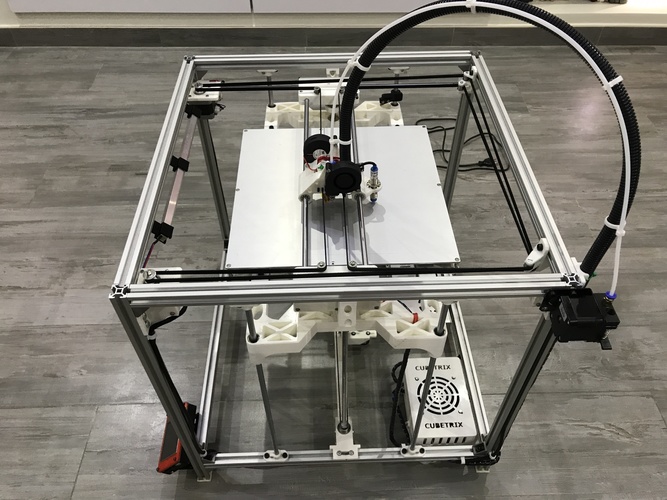

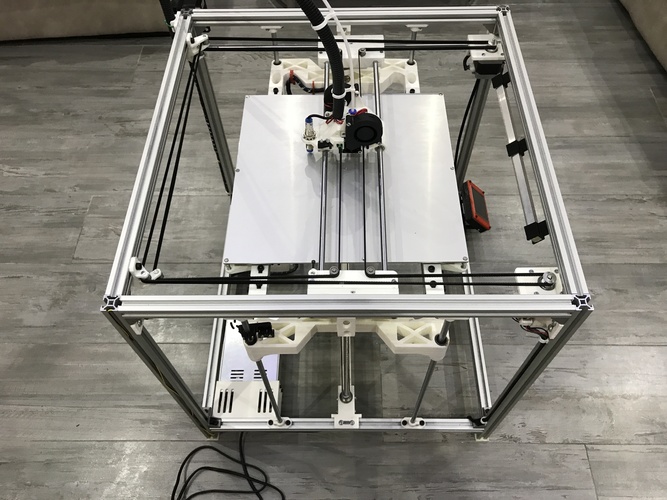

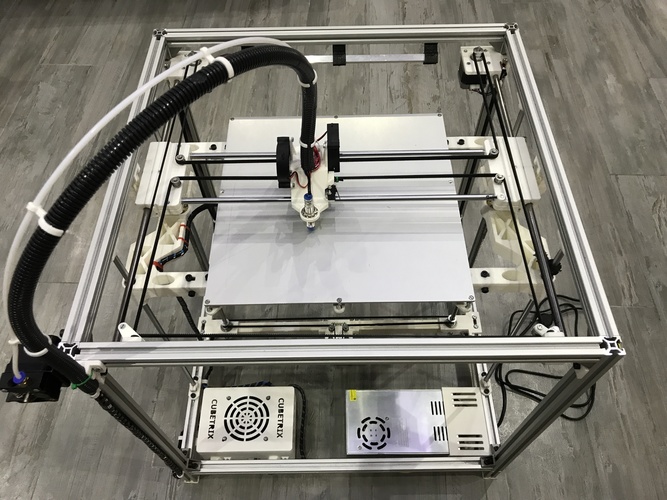

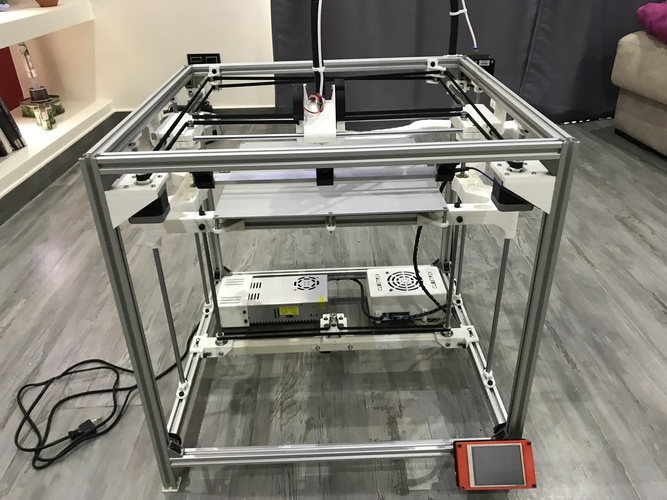

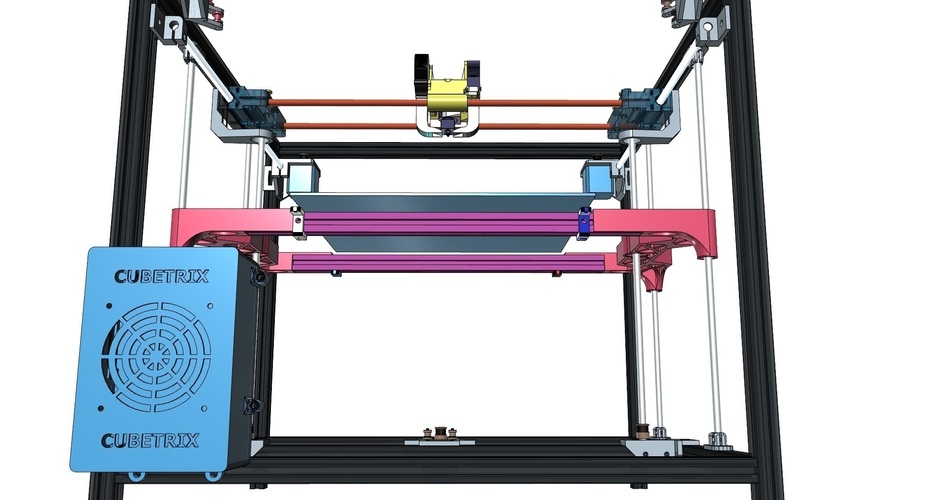

Every 3D print starts as a digital 3D design file – like a blueprint – for a physical object. Trying to print without a design file is like trying to print a document on a sheet of paper without a text file.This design file is sliced into thin layers which is then sent to the 3D printer. Chuck Hull invented the first 3D printing process called ‘stereolithography’ in 1983 and from this priciple, he built the foundation of what we now know today as additive manufacturing (AM) – or 3D printing. In the same way ( almost ) I did it myself from a dream turned into design to create my own 3d printer with the name CUBETRIX.

Thanks to open source we can program our printer to create almost any object. As many of you have at home a prusa i3 clone with which I have spent more money than it should be spent: that if you have to modify the structure, that if you have to change the extruder and the list goes on and on and I decided to get down to work and create something much, much better at a price of a prusa clone.

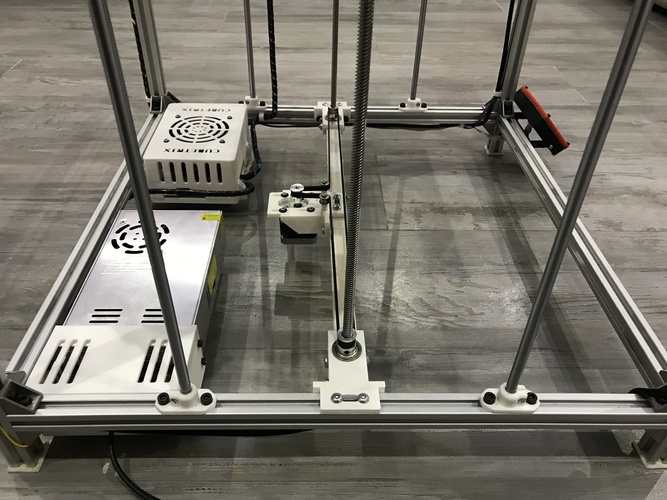

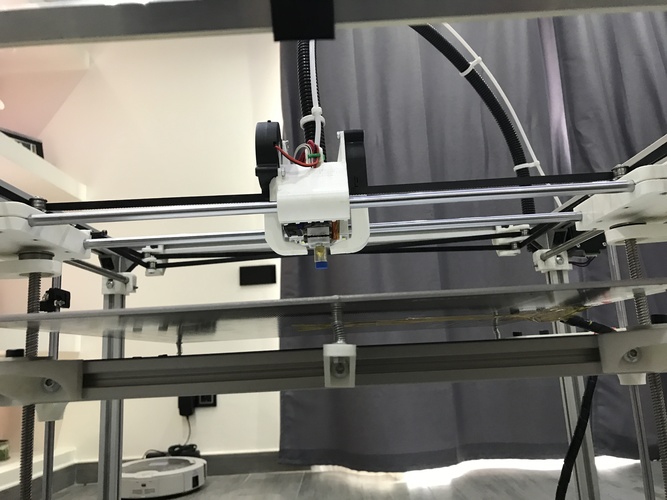

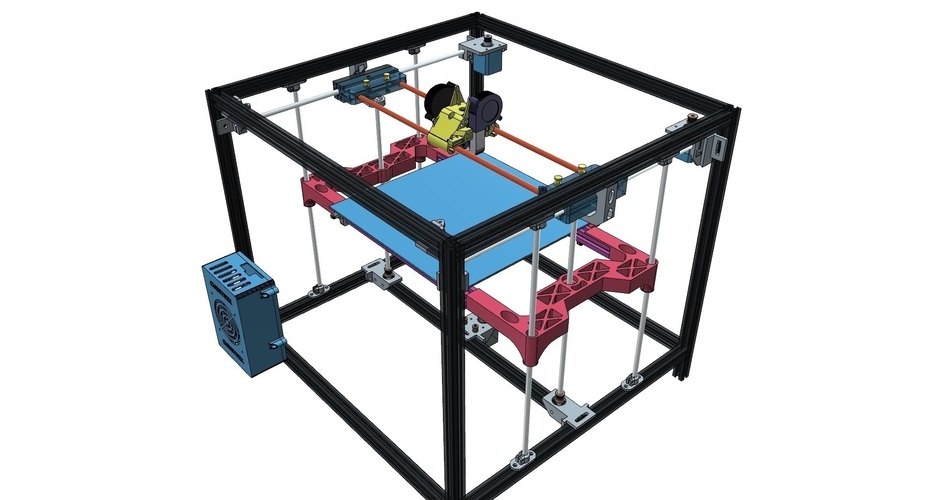

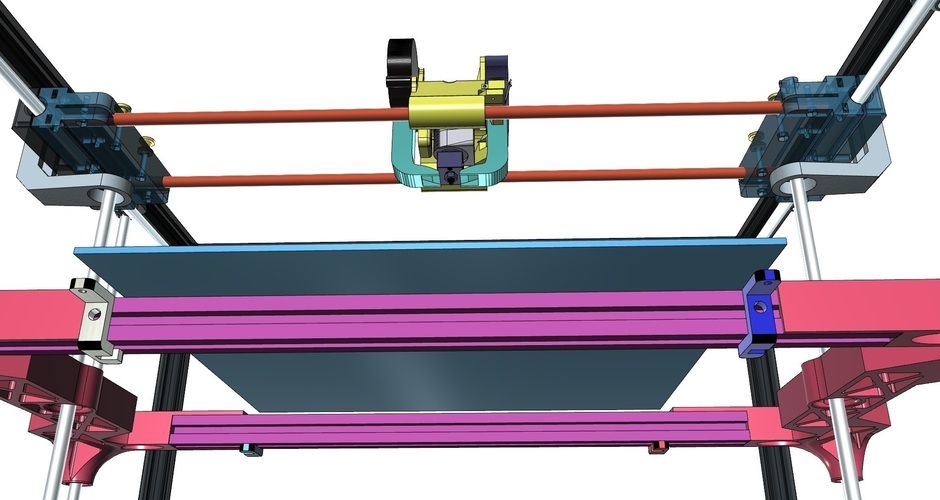

CUBETRIX has 330x330x300 printing area, 32bits processor,32 steps per motor, 3.2 inches tft touchscreen, wlan and wifi conecion,10 times superior velocity compare to a i3 prusa clone,6 points autolevel ( depends of your config.) , very stable structure no more rare movements, leds on the extruder to better view of the prints, etc…….. But you can add any board/lcd you like: duet,ramps,etc… on this printer. Without more ado I present my project: With the files you will get the pdf on how to build/view the structure and the BOM (bill of materials )pdf file and for those ho whand to see it we have it in the link below.

(Note: If you intend to make a larger/smaller print area, then increase/decrese the length of the 2020 extrusions AND rods for each axis by the difference)

BILL OF MATERIALS here:http://j.gs/Bzcs Any components for 3d printers here: http://j.gs/Bzct

Everyone is going to say: Yes we have the files, but how are we going to build the printer, So comrades I have created videotutorials on how to build the CUBETRIX. Here there are:

No:1, No:2, No:3, No:4, No:5, No:6, No:7, No:8, No:9, No:10, No:11, No:12, No:13, Homing test, Movements, and finally printing, Z axis weight torture test, Time laps prints.

Here is the CUBETRIX Facebook group for more help and improvements/discussion.

To configure the motherboard more easier I attached the firmware to the files.

Happy building/printing guys.

Comments