Prints (0)

-

No Prints Yet

Be the first to upload a Print for this Design!

Description

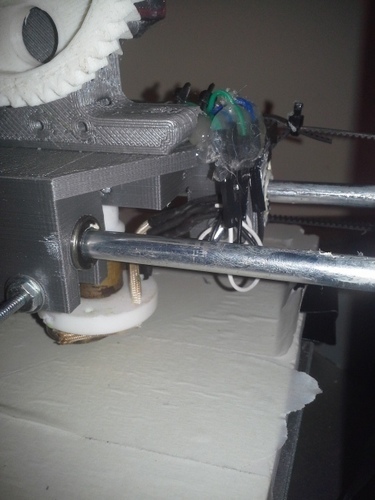

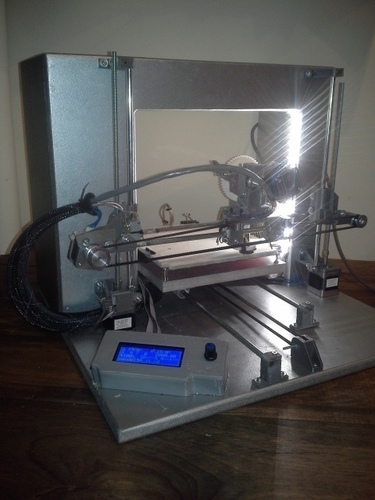

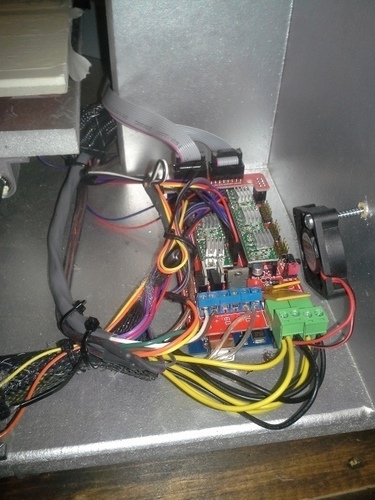

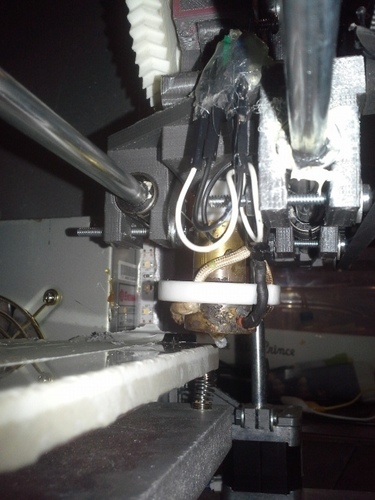

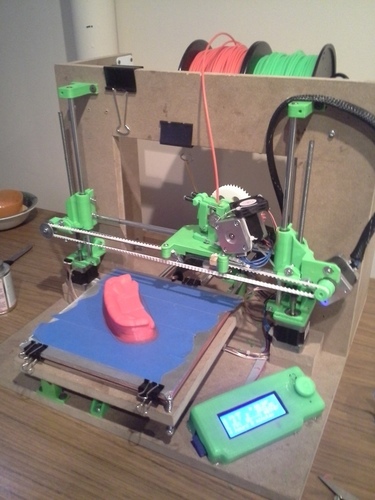

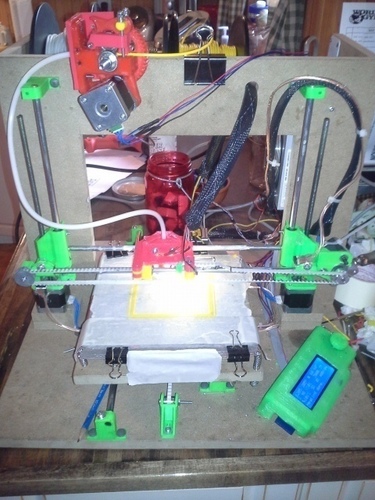

Summary First, I wanted to have a solid 3d printer for as cheap as possible. So I choose the model mendel 90 because there is not that much printed parts and the body is made of mdf and I'm used to work with it. So looking at the plans and "vitamins" I realized it was going to be hard to make it for cheap: as I am in Canada (Québec, sorry for my English!) It was hard to find metric stuff. So I decided to work on plans to make it with imperial stuff for rods, bolts, nuts. etc. Before I get started, I also removed from the original design every thing that is not essential to get printing. This printer can be built for less than 300$. So here are my main changes: I used 5/16 smooth rods instead of 8mm (7,94mm) I used lm8uuaj: ajustable linear bearings For this reson, every bearing mount is designed to be screwable. So you screw the bolt and nut just enough for it to be stable but not too much so it can move freely. I redesigned the extruder to fit 6-32 screws and be more solid (I'm not the first to do that, but...) I worked on the x carriage to find a good optional way to easily install the extruder with a bowden tube, or not! Also I fixed the j-head style fixation for hot end directly on the x carriage so that if there is a jam, you can work on it just by removing the extruder or the bowden adaptor, but still solidly installed on the x carriage. I changed the place where the back pannels are so that it protects your psu and ramps. But it also allows you to put some more plastic spools. I simplified all the wiring that was so complex on the original mendel 90. now you can just use normal wires with tie wrap And the beauty of that desing: you can (have) to use your imagination to make your own printer. I mean for mdf panels, cut the size you want, same thing for rods. With these printed parts you could build a 24x24x24 inch 3d printer if you wanted. Just use longer rods and bigger mdf pannels! "Bowden" and "lcd case" are'nt essential to make that thing work. Some improvements to come: -a little modification to the extruder so that the gears are easyer to align. -Add end stop switch bracket on both sides (x motor and x idler) so that you can chose on wich side you want to put it. Add a plastic plate to glue hot end plugs on x carriage. En passant, si t'es à Québec et que ça t'intéresse, j'en ai quelques unes à vendre de ces machines!!! Instructions You can inspire yourself from the official mendel90 reprap page... http://reprap.org/wiki/Mendel90_Build_Manual But understand that there will be several changes! I used ramps 1.4 lm8uuaj bearings and 5/16 rods J head style hot end 6 5/8 screws and washers 6-32 bolts and nuts of many length 2 meter of timing strap with metal pulley 8x8 heated bed lot of patience! I'll add videos of assembling as soon as possible! https://www.youtube.com/watch?v=hbSo27Q2qHo

Comments