Great Printer

It's easy for use (software) but it need more experience with another printer (hardware)

It's easy for use (software) but it need more experience with another printer (hardware)

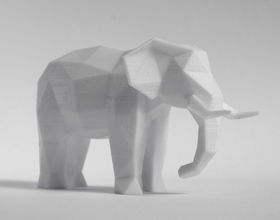

Good results after some tweaks, very satisfied with the results

It's for beginners

Hi, on first, English is not my mother language so, i m gonna try to express my self clearly.

It's not a very long time that I'm owner of my prusa I3 from Anycubic. It was quite easy and interesting to build it, just a bit long.

For the principal subject, the printer is doing her job. For the price i was not expecting a Profesional quality but i m quite happy about the final result. Its only few days I'm using it so, I don't have back review about it. I well share my experience after more uses.

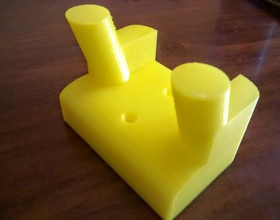

I got it as a kit, it took me about 6 hours to build it and a couple more to get it working. I works good,just needs time and experience with the settings

Started as a standard i3 build....but can't resist tinkering

1/ Encased totally in perspex

2/ Made custom hotend in lathe ---- similar to E3D

3/ Converted hotend to water cooling ---- Water jacket, pump, radiator and fan, thermometer.

4/ Installed auto levelling

5/ Upgraded hot bed by sandwiching two together...uses about 17amps....so 2nd power supply and switching with

12V car relay.

6/ Installed lighting, and auto shutdown, using Solid State Relay and M80/M81

Been going well for a couple of years, despite the cheapo Chinese electrics.....love it !!!!!

I spent 3 days to assembly of Anet A8 (on my free time). It was 10 days and I didn't calibrate it properly yet. But it is cheap! But if you have more money and want to quick start in this business I don't recommend this printer.

It's a good printer with some challenge. It have some trouble with positioning and leveling of Z-axis, but it solved with some printed parts and manual after-setting. It can upgradeable because the software has no size limit.

Cheap and usefull if you like a fight.

Out of the box I knew it was going to be a challenge to build it, which it was, but I had fun thinking of the fruits of my labor that were to come. Everything went together fine except on part was broken, that was the Y axis (Heat bed) tensioner, I did message the ebay seller and they sent a metal replacement out, but I had glued the broken part back together anyway (which is still going strong about a year later) At first I had issues getting it to extrude, this turned out to be bad earthing on the board, after continuity testing the extruder tracks in the board, I soldiered a wire between the 2 joints and it started working. Days of testing to try and get the printer to print "ok" and trying different things to get the print to stick to the board, I finally printed a skull, about 3cm by 3cm, not amazing but it did show me the limitations on overhangs and detail, since then ive installed a new extruder and am looking in to a better stepper motor for the bed axis as it will jump now and again when under a bit of load, which cause the print to become off center, but overall a very good, cheap intro in to 3d printing which can be fully upgraded to the point of not being the same printer you started out with!

Cheap and cheerful, extra bolts and nuts included as is extra y-motor bracket. Mechanics are generally ok, the most annoying feature is the CTC:s own(?) GT2560 firmware. I'm waiting for another motherboard to arrive, then I'll try to flash this one...

Have fun!

Roisi

Update your browser to view this website correctly. Update my browser now