Easy to use

I like the "skeletal" look of this printer. This makes it easy to replace various parts.

I like the "skeletal" look of this printer. This makes it easy to replace various parts.

Easy to assemble and get first print going. Really appreciate the quality of components. First "real" print after a few calibration cubes (and online research for correcting setup issues) was a filament guide/holder. Took a couple of tries, but finally figured out that my drafty garage workbench was not the right place to set the printer up. Lots of little improvements (tweaks) are available via the internet and every one implemented so far has made this printer a little better. I fully expect that as I gain experience and knowledge this printer will continue to impress me with its capabilities and value. Very satisfied.

buena calidad.facil de usar

Purchased the kit from China back in 2014. Cost was around £320 (including customs duty) and included 2 x 1Kgm rolls of filament. It was based on Prusa i3 but had an acrylic frame, not aluminium as the later ones moved to and it did not have auto levelling. The Z axis did have two motors with 'built in' lead screws (supposedly better than lead screws that are clamped onto the spindle). Kit was easy to put together and doing this gave me a good intro to how it all works. It also worked straight away! Have used it to print a few useful objects as well as many 'frivolous' ones.

Overall it was a good buy at the time. But now I am looking to do some more intense/precise printing and I realise ideally it needs better calibrating, larger prints have the habit of warping, the Z axis motors started 'skipping' (and finally jammed) and ideally one needs auto bed levelling. However, so far I have been able to correct the jammed motors (stripped down and gunk removed from threads and inside motor) and am planning to build a simple enclosure (to get more stable temperature to hopefully reduce warping) and to add auto levelling. Also need to perhaps straighten the Z axis lead screws as these may cause some skips plus see if the nema 17s should/could be plugged in to two connectors (the board has an extra E1 socket that Marlin could make a Z2 socket). Again this is proving to be an interesting learning experience.

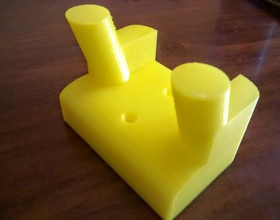

I did print and install two filament guides. One allows filament to loop to top of machine then down to extruder and reduces any strain on filament when executing fast moves (occasionally I had filament breaks). The other sits in extruder and allows the use of flexible filament. Also printed some cabling bracketsto tidy up the runs and some 'hold down' brackets to screw printer and filament holder onto a base board.

Pros: Price; Good Quality; Instructive; Lots of data on web; a few spares provided and mostly commonly used parts that are easy and inexpensive to source.

Cons: Lead screws slightly warped; No data for Arduino board used (so will be making a guess).

One other positive for me is that it has got me interested in all aspects of Arduinos, 3D design, general CNCs, and even programming in Python. All good to keep the brain ticking over!

I feel for the price it is a great way to see if your really into printing 3D models.

The build took a few days. The first few prints went great. Needed some tweaking. Tweaking led to flashing firmware, which led to breaking the heat bed and have no LCD. Once I actually found the correct firmware and replaced the heatbed everything works again. Now I’m back to tweaking the print settings as my prints are not very pretty.

Great way to learn how to master a 3d printer as well as learn and practice A LOT of patience and trial and error.

After waiting for 6 weeks for the kit, I spent a whole day assembling and testing. I have 50 years of experience in mechanical and electronic design and assembly.

The assembly instructions come in a one-half inch book of color pictures and text; a really great job.

I only had a couple of minor instances where I failed to read the directions and had to back up a step or two. Wiring everything into the controller is quite a challenge since there is a lot of wiring stuffed into a small space, but the directions and good pictures saved the day.

After running the self test (success!) I proceeded to the calibration. This is where you need to take a break and take your time. This is the most critical part of the build.

Once the testing was done, I printed the Prusa logo from the SD card. It was just about perfect.

The next day I attempted to print some small parts and was having trouble getting the PLA to stick to the bed. I went back and did the first layer calibration again -- I think I had the nozzle just a bit high so the PLA was not bonding well. And always keep in mind that the bed must be clean, clean, clean. Any residue will cause you grief.

This is my third attempt at 3d printing -- the first two were utter disasters. Hats off to Josef and his team; this is really a fine machine.

Very good!

Cheap printer, but very friendly to explore and work with. Comfortable and useful soft for both operating systems.

I build 3dmodel airplanes from 3DLabprint.All of their designs have been optimised for the Pruser Original printers so I just use the GCodes directly to print the parts.

Update your browser to view this website correctly. Update my browser now