Prusa hephestos

Good machine. Take's a time to handle it , but it can give you profesional results.

Good machine. Take's a time to handle it , but it can give you profesional results.

Does work, there are many options to tweak

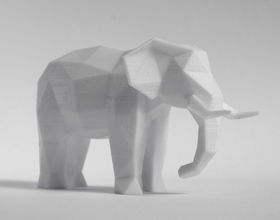

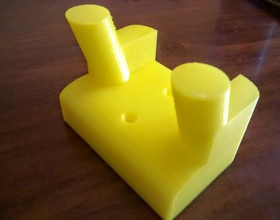

I love this OFFICIAL Josef Prusa i3 machine. In fact, it such a quality printer that I used it to replicate itself. The parts printed flawlessly. I have printed quite a few miniatures, drone frames, prototype parts, toys, etc with this thing and it keeps running perfectly! I have even had a 40+ hour print that came out immaculate!

I would recommend this printer hands down even over some of the more expensive printers!

http://shop.prusa3d.com/en/3d-...

Buy it, you wont be sorry!

Max

First I want to say that this is probably not the best option for someone just starting out with 3D printing or someone with no technical experience. I have built 3 RepRap Prusa i3 printers and each one has its unique features and advantages. I would strongly recommend getting one in kit form because you will gain an enormous ammount of knowledge on how the printers function, printer construction, and the satisfaction knowing you built it yourself. There is a wealth of knowledge online on opperations, tweaks, and upgrades. I have found very few programs that don't support the RepRap Prusa i3 and the ones that don't are for proprietary printers. Operating costs are low compared to several of the name brand printers out there that require specific filament and proprietary parts and software. The print quality is going to vary depending on software, filament, machine configurations and experience. I have found that they don't seem to be a finicky when it comes to filament and they support a wider variety of filament types. I have ran ABS, PLA, WOOD, and HIPS through the same printer only having to tweak some printer settings and still getting quality prints. Many of them have large build areas so you are able to print much larger parts then many out-of-the-box printers. Operating the printers is pretty straight forward with easy to navigate menus and user friendly software. Parts are readily available online along with an extensive library of troubleshooting, upgrading, and software. Some of the drawbacks are that you don't usually get a warranty except a small one on the parts and you will have to do the troubleshooting and repair yourself if you have an issue. The advantage is that parts are inexpensive and it is easy to have extra parts on hand in case of an issue and you don't have to rely on someone else to repair you printer in "their time" or have to worry if a company will still be there to support you. If you have the time, skills, and knowledge I would strongly recommend this type of printer for you.

satisfy with my DIY kit but i Will buy the new Prusa I3 Mk2 for the futur.

Prusa i3 is best to be scratch built. It enables you to learn the electronic and mechanical aspects that goes into a 3D printer. It took me about 3 months to complete my build of my i3. This includes research, designing and sourcing of all the parts. What I love about an i3 is the fact that it is easily modified. Over the time since completion I have made many modifications to my needs. This as far as I know is not easily done on other printers. As I have not been exposed to many other printers, in my opinion I would say this is an easy printer to use. With the help of other i3 users I believe that this is one of the easiest 3d printers to learn and use.

Whether this would be the printer for you depends a lot on your skills and expectations. I am an embedded systems engineer who loves to tinker and hack (hardware and software). I have a sound understanding of mechanical principals. With that background, this printer has been great.

My wife gave me the printer kit as a Christmas gift (after I spec'ed it out for her). It was purchased from China via Ebay. The model/manufacturer was not even mentioned on the Ebay listing (it was just billed as a Prusa i3). I figured it out after finding a folder in the SD card called 'M505' and doing a google search to find out the rest. The price was right, among the lowest price of i3 kits available in late 2015. This is my first and only 3d printer. The kit is complete, but is a somewhat as-is, your on your own type of thing. It came with an SD card which contained the 'manual' (a series of pictures of the kit in various stages of assembly). If you need or want a step-by-step, you should probably look elsewhere. If like me, you love a puzzle and a challenge, I would definitely recommend it.

The printer, in its present form, produces a print quality that rivals commercial machines costing several thousand dollars. In its original form, it produced decent prints, but nothing spectacular. I have made many modifications and upgrades during that time that I've had the printer. Probably the only thing still original is the frame, motors and lead screws. Don't expect the cost of the kit to give you a long term, durable machine. It won't. The first thing to go was the control board (a mass produced Melzi v2). I went to turn on the printer one day, and nothing happened. I did some trouble-shooting and determined that the voltage regulator had failed. I replaced that with an inexpensive 12v-in, 5v-out automotive voltage regulator. That got me back in business... for a while.

I asked my wife for a E3D v6 hot end for my birthday. This resulted in a huge increase in print quality. It also pushed my power supply over the edge. One day, a couple hours into a print, I smelled an unpleasant odor. I looked over at the printer and saw smoke coming out of the power supply. The supply that comes with the kit is a 15A supply. That was borderline sufficient in the original configuration. When I added the E3D, it just couldn't handle the load. I purchased a 30A MeanWell 12V supply to replace the original. I've not had any trouble since (with the power supply, that is).

One day a couple of months later, the printer stopped in the middle of a print. I noticed that the voltage regulator was very hot. I decided to just bypass the VR and power from USB. I started the print again. A little while later, I saw smoke. Some component on the board had failed, bridging the 12V side with the 5V side. Rather than fix that board, I decided to purchase a more reliable controller. After a bit of research, I decided to go with a 32-bit board. I chose the Azteeg X5 mini. This board runs Smoothieware firmware and produces noticeably better print quality. The only problem is that Smoothieware does not support the LCD panel that comes in the kit (a 20x4 parallel LCD with a 5-button analog interface). I ended up purchasing a RepRap Discount GLCD to replace the original display.

In all, I probably have $500 invested thus far. Still far less than the least expensive commercial solution, and with a print quality rivaling a printer costing quite a bit more. I have enjoyed every bit of it (except for a few frustrating moments). The experience has taught me a lot about 3d printing. I have learned what causes certain artifacts in the print, and how to resolve them. The only artifact that remains is a small bit of ringing in certain situations. I'm still trying to figure out how to completely eliminate this, but am beginning to come to the conclusion that this is one of the downsides of this printer design. The problem can be mitigated to a degree, but not totally eliminated, just due to the physics involved. I'd be very excited to find I'm wrong about that though.

Le mécanicien que je te suis admirer les techniques de solutions Simples Retenues Pour la construction d'Une machine à robuste, économique et A SES needs adaptables. De bonnes connaissances heuristiques en technique des machines outils are la bienvenue.

Easy to use and to keep running

It was fairly easy to put together but the information that is most important was not included with the kit I got. Only someone who likes doing research and finding their own answers can appreciate the treasure hunt \i had to go on to figure out how to make it work well enough to print anything. Do yourself a favour if you are not mechanically inclined and do not enjoy tinkering with your machines and do not get one of these - they are not for people who are looking to play around at 3D printing. That being said, it has been an intriguing and rewarding journey and \i have printed a large number of things, each of which taught me something new about fine-tuning the printer and upgrading components to meet my printing needs. In only five weeks I have had to replace all of the linear bearings for grinding and wear as they do not stand up well to nearly constant printing finely detailed objects at what I now realize were very speeds. Be prepared to have to repair and replace various parts and components and make adjustments for a lot of the things that you will be printing. For me, as a Field Technician, I love this printer and am amazed at the potential it has to create objects I couldn't find easily in the marketplace. Many times I have caught myself mesmerized, watching the printhead go back and forth filling in the spaces that will become something useful or decorative. So if you like hands-on hobbies and are willing to put up with a bit of research and, honestly, a bit of frustration, this type of printer is definitely one to consider. Make sure you find a good support group or source of information (there are literally hundreds of them out there) because there is no substitute for sharing experiences with people who are engaged in the same activities you are. Hope this helps you, and HAPPY PRINTING.

Update your browser to view this website correctly. Update my browser now