Prints (0)

-

No Prints Yet

Be the first to upload a Print for this Design!

Description

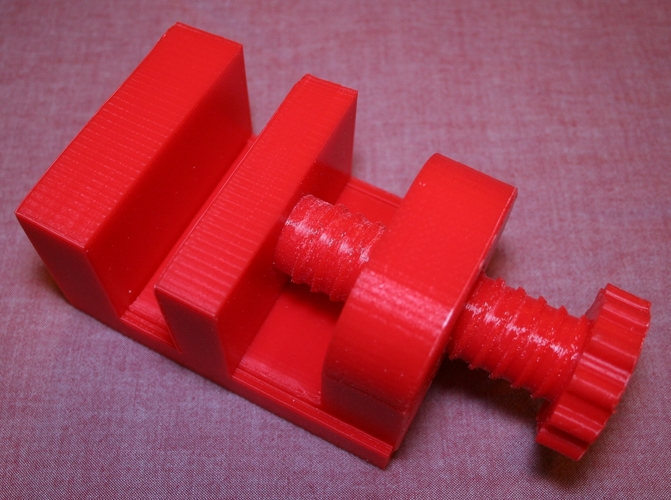

I needed a small vice to hold things in place when I solder and glue stuff. This is my first, you can see from my 3D printed parts that the new pieces are modified to make them even better. GLUE the two bases together using the two 10mm pins to hold them together. When printing the "ScrewEND" part have the larger hole down so the clamping face is nice and flat at the end of printing. The rats nest inside the 25mm bore makes it easier to glue the 3mm metal screw into the big plastic vice screw. I wipe off the end of the plastic screw after pushing some Gorilla Glue down into the hole so it doesn't glue to the end block that needs to allow the metal screw to rotate while opening and closing the vice.

I needed to use a pair of pliers to get the threads started the first time, not sure why, but once I got the screw going it worked well, although maybe a tiny drop of oil or grease might help smooth out the rotations.

miniVices

Comments