Prints (0)

-

No Prints Yet

Be the first to upload a Print for this Design!

Description

Summary

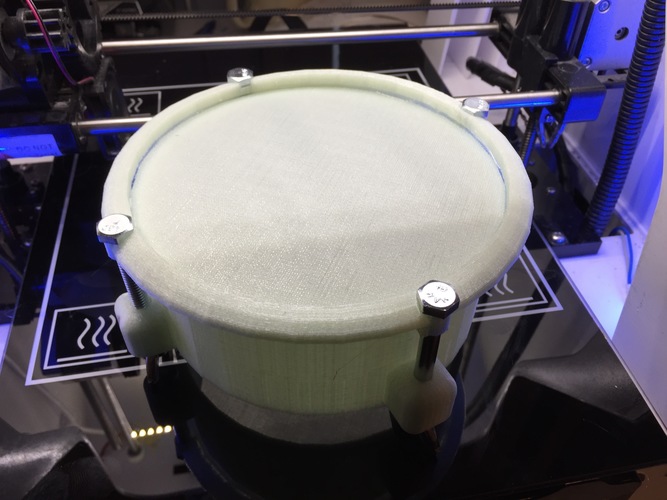

Wanted to make an actual tension/stretched skin drum completely from 3D printing -- so I did. This drum uses 4 quarter inch bolts at least 2.5 inches long to draw tension on a head; similar to a standard drum you see on a drum set or marching band. Except -- this one is entirely made of PLA (or what ever you choose) and is 3D printed. I only played a little bit with my sticks at 3 inches (pp if you want a dynamic marking); I was too nervous to break it to really lay into it. It does however play well with fingers. Considering I thought it was going to break I'm quite happy with it.

Print Settings

Printer Brand:

Robo 3D

Printer:

R1 ABS + PLA Model

Rafts:

Yes

Supports:

Yes

Resolution:

High

Infill:

30%

Notes:

Only the Rim needs a Raft and Support, everything else I was able to get to print without them; but know your printer, maybe you won't need it. Feel free to experiment with different infill levels; for my prototypes I use 30% consistently. This does have some long prints -- over 10 hours on my Robo 3D for the shell.

Post-Printing

After everything is printed rafts and supports are cleaned off. From here you would assemble the drum exactly like you would any other. Before you put the head on line up the rim with the shell. I didn't quite get things centered perfectly; it does fit but only in one spot.

In case you don't know how or have never headed a drum here are the steps: (After lining up the rim) 1) Place the drum head on top of the shell with the curve going down. 2) Place the rim on top of the shell and head. 3) Put the bolts through the holes of the rim and shell and put the wing nuts on VERY loose, just enough to keep them there. (With this drum I flip it upside down after I put in the bolts to make it easier to put on the wing nuts) 4) Tighten slowly -- it is a plastic head after all. Tighten exactly like a car tire just not as intense. Pick a spot to start then go straight across, then almost across then straight across all the way around the head. (this drum only has 4 lugs so all the way around the head is 2 times. In the video you can see me do a quick tighten to get the drum higher in pitch)

Also if anyone prints the head with a stretchy material I am interested to see if/how well that works out. Might need to tweak some things -- might be better -- might not make sound or perhaps better sound. Also, might hold up to sticks better.

Comments