Prints (-3)

Description

This is a working, as tuned as I can get it (Breath pressure affects tuning - I have trouble determining if I'm increasing my pressure consistently as I rise in the scale), 12 hole sweet potato/transverse ocarina. Sound sample:

So far every print I've done of this version (v13, took a while to get those last two notes to sound) plays the full range - but ONLY once I remember to clean out the windway with a safety pin or other small implement after printing. Any stringing or deposited extra plastic in the windway can weaken the notes, and lose the highest ones.

I have only printed this model in PLA - I do not know if the contraction of ABS would stop this from working, so if anyone tries that let me know :)

I hope someone out there enjoys this!

Edit: Added the triforce as separate pieces you can glue in so they can be different colors. There's a version that sits flush with the ocarina, and a version which is 'outdented' (Which google said was an acceptable word but Firefox Spellcheck disagrees.)

V17: This one seems to have a slightly sturdier high note. Hoping it fixes the issues some people have reported.

PRINTING:

- Use at least 3 perimeters - air cannot escape into the infill or it probably will lose the high notes, or all notes.

- Print in either the orientation of the file, or standing on the larger end.

- Use supports touching the build plate - not internal ones.

POST PROCESSING: Clean the windway with a safety pin. I often get one really annoying blob of plastic right in the center towards the windway exit for some reason, and I have to dig it out. Any strings in the windway or across the voicing window can also affect the sound.

Also pull out any stringing you can from the internal chamber of the ocarina, and finger-holes. They do seem to be able to affect that high note a bit, which I honestly didn't predict.

My Slicer Settings (In case it helps): I use MatterControl as a slicer.

0.2 Layer Height 3 Perimeters 1.8mm Top Solid 1.6mm Bottom Solid

10% infill, Lines style. Starting angle is 45º, pretty sure I changed that ages ago for a specific print and forgot about it. Infill overlap is .06mm.

Infill speed: 60mm/s Top Solid Infill: 45mm/s Inside Perimeter: 50mm/s Outside Perimeter: 40mm/s Non-Print Travel 150mm/s

Brim of 3-6 loops for adhesion of some of the thinner supports.

Printing temperature 205º (I use this for all the PLA filaments I've tried: Robo 3D, 3D Solutech, Makergeeks, Hatchbox 3D, and IXCC) 55º-60º bed temperature depending on whether or not I'm cold and convince myself that it'll warm up the room a little.

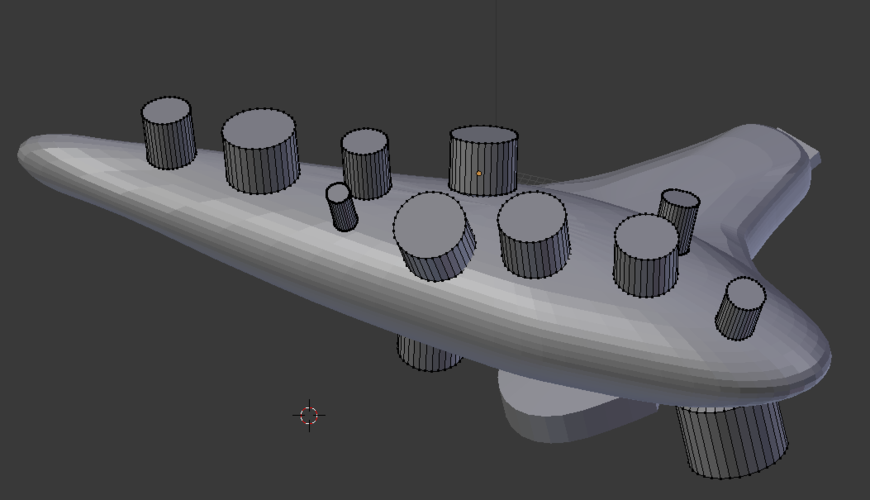

How it was made: Made in Blender 3D. I had been thinking of a way to ensure the ocarina would be easily editable to increase the speed at which I can update the voicing/windway to get the high notes, and came up with this. It's probably nothing new or earth-shattering, but it worked out really well for this project. For every piece of the ocarina, including the negative space (hollow center, fingerholes, etc) I created an object and aligned them. This allows me to easily change dimensions or fingerhole positions without having to modify the vertices and end up with some ugly surfaces as a result. This is the weird grey image I've included.

Once I'm happy with my edits, I use boolean operations to merge or remove the pieces from the mesh, and it ends up mostly as you see here. I do a few quick manual smoothings just to make myself happy, though.

I really like the way it all worked out, and will probably do that again when I move onto making dual chambered ocarinas.

The only issue with this process is it made it a bit hard for me to blend the mouthpiece into the body of the ocarina. That seems more like a lack of experience on my part than a flaw with the process, though. I may release future versions that smooth it out.

Comments