Prints (0)

-

No Prints Yet

Be the first to upload a Print for this Design!

Description

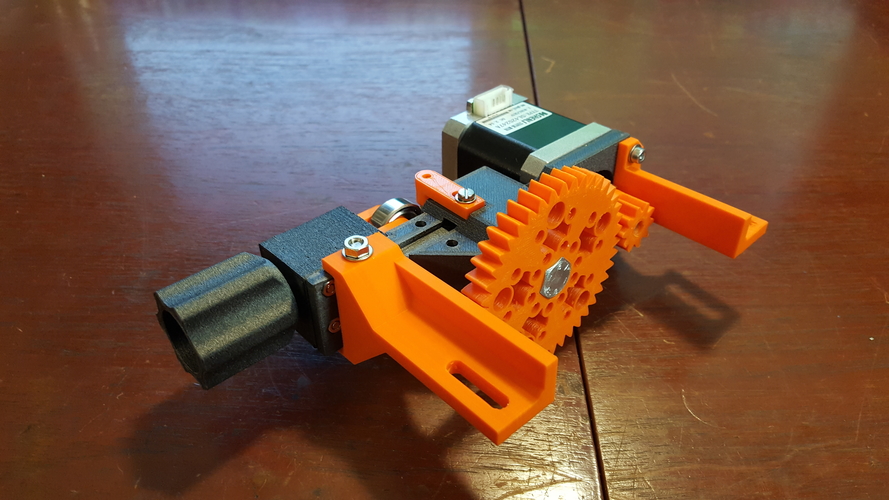

Geared Extruder 3mm Filament

***************************************************************************************************************************************

note: April-10-2018

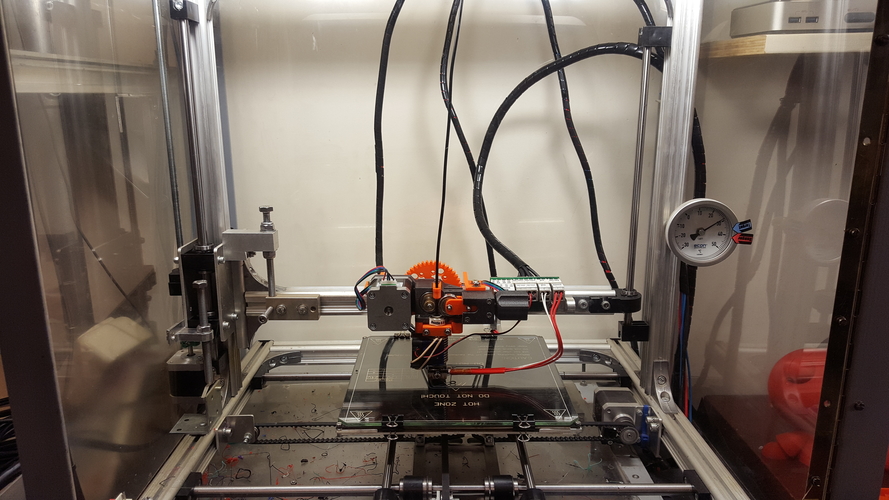

This Extruder works very well and worked many hours for me now.

Later I placed it in a closed housing for ABS printing (temps inside the housing up to 45°C) and came to the conclusion the main body warped slowly.

Conclusion:

This extruder works very well outside an enclosure.

Inside an enclosure with high temperatures it does not. Instead you could use : https://pinshape.com/items/445...

***************************************************************************************************************************************

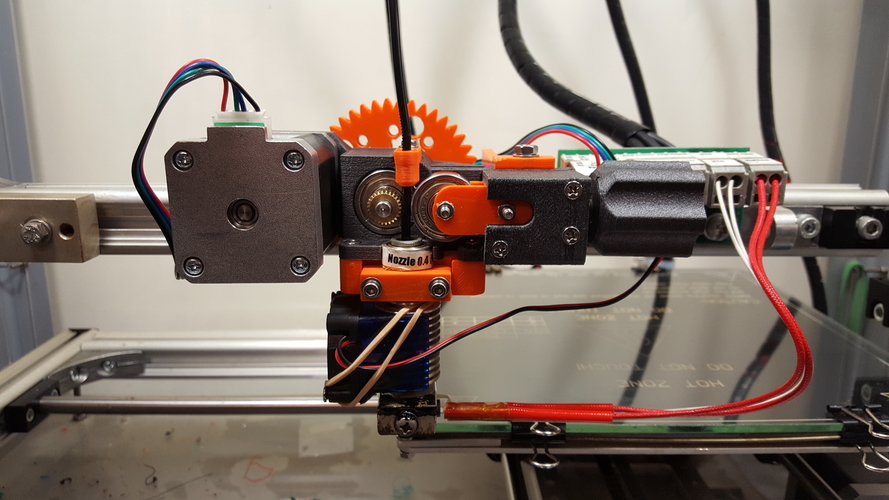

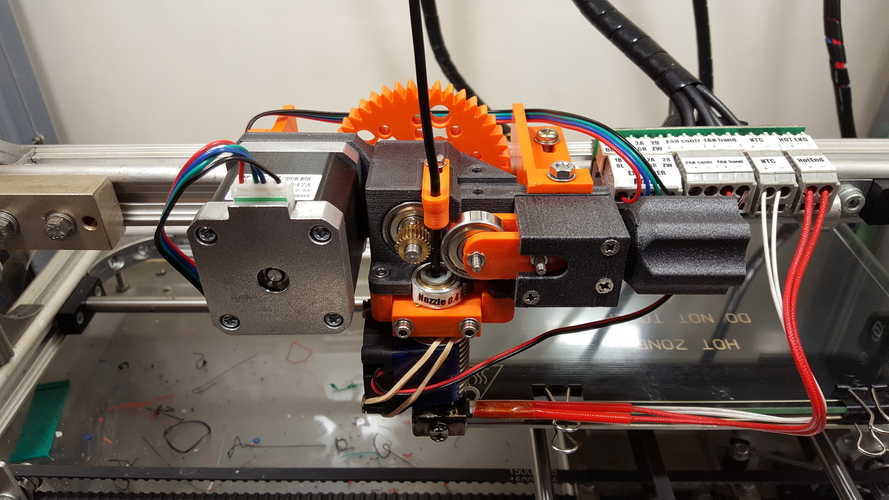

This is a Geared Extruder that can be used for 3mm filament.

Of course you also could use it for 2.85 and 1.75 mm :-)

I made this one to fit to the K8200 of Velleman because the old extruder did not want to go any more. The gear ratio is still the same as the old one so there is no change needed in the firmware

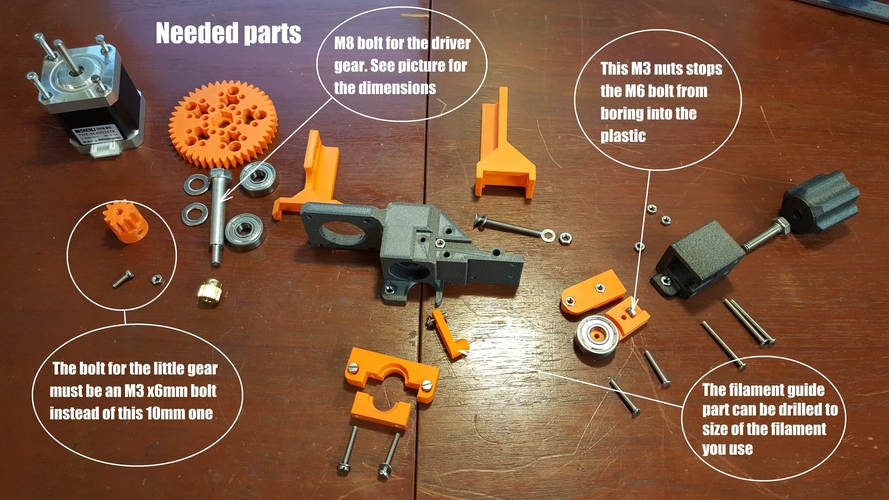

The filament guide part can be drilled to size of the filament you use.

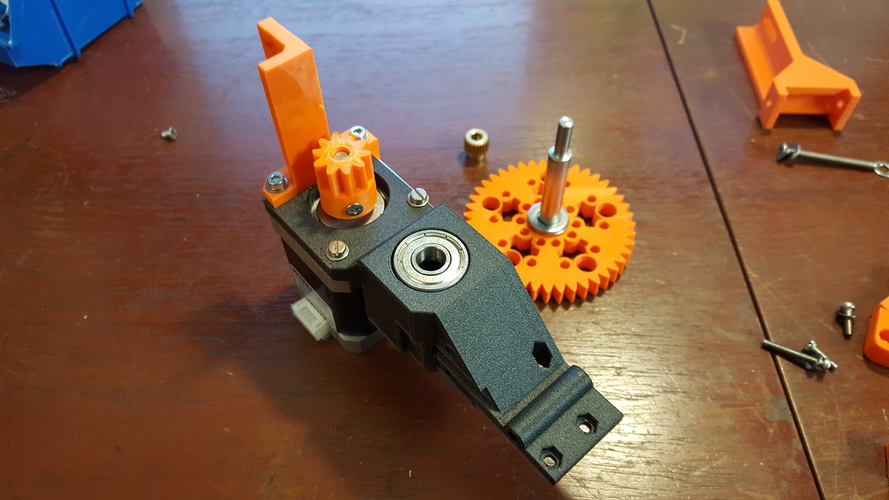

The driver part of this Extruder is an M8 bolt that is turned down to 5 mm on the end to fit the filament driver gear. For the dimensions please see the pictures.

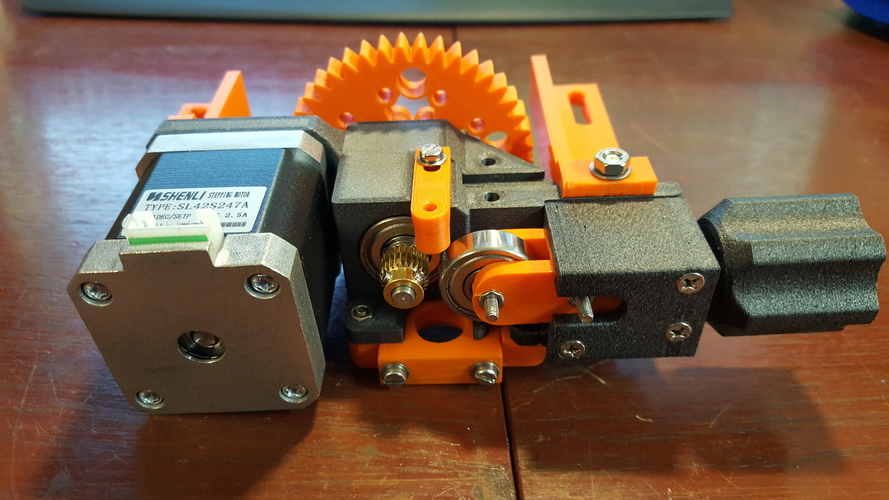

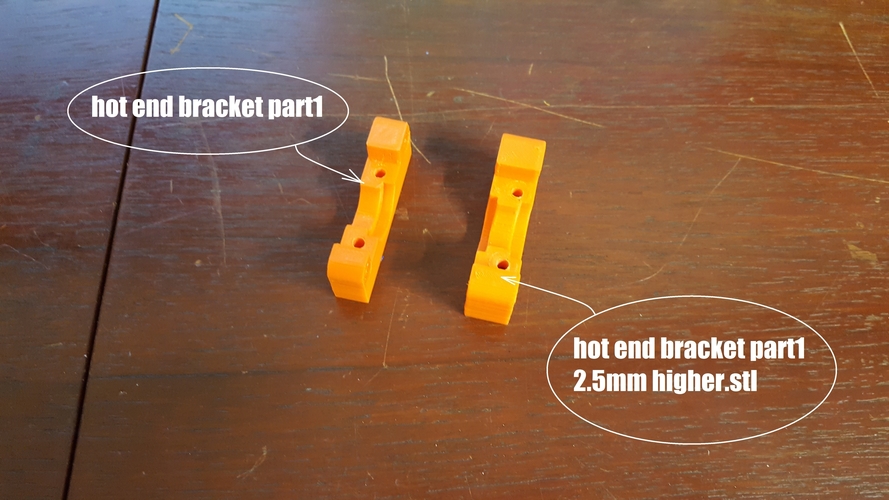

The part “hot end bracket part1.stl”can be changed for “hot end bracket part1 2.5mm higher.stl” if you Hot End is higher. I first wanted to use a cheap Chinese Hot End but later switched to a Europe made one and the Bowden connection makes this one a bit higher. For that I had to make this “hot end bracket part1 2.5mm higher.stl”.

For the additional parts please see pictures :-)

small gear has 10 teeth and the big gear has 43 teeth

The dark gray parts are printed in PET-G Carbon and the Orange parts are printed in ABS.

***************************************************************************************************************************************

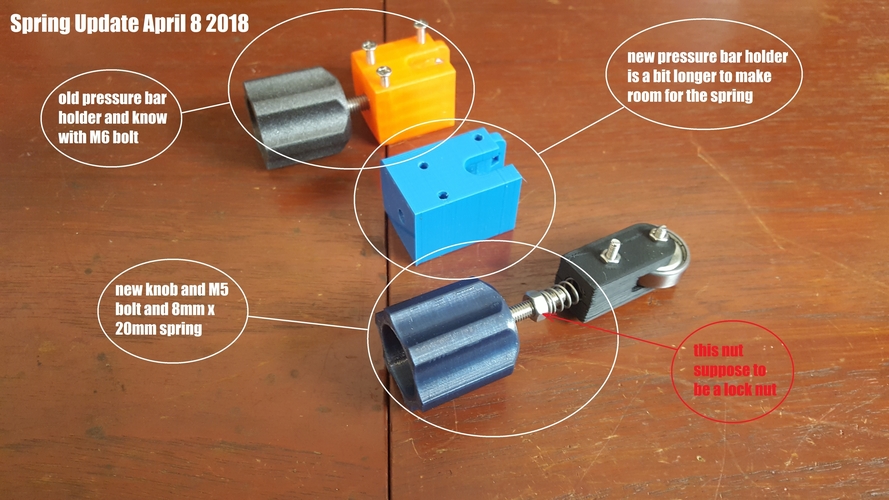

April 8 2018 Spring Update

After using this extruder with great success without a spring, I did encounter problems with a specific filament. Turns out this filament wire was not equally round on its length. It resulted in extruder failures because the filament bar didn't flex with the filament. So when it got to a part of the filament that was slightly thinner. The filament slipped on the driver gear. So I decided to incorporate a spring. Yes I know, I should done this from the beginning, but at the time I wanted to make this extruder as simple as possible. Now I know a spring makes it more reliable :-). Also the spring makes adjusting the pressure on the filament a bit less critical.

Please see additional picture.

* new pressure bar holder is a bit longer to make room for the spring

* new knob and M5 bolt and 8mm x 20mm spring (beware, the old bolt was an M6! But it took to much space)

-

pressure bar modified for the spring

***************************************************************************************************************************************

Parts list:

1X M3 x6mm bolt

5x M3 x 10mm bolt

6x M3 x20mm bolt

3x M3 x40mm bolt

12x M3 nut

7x M3 washer

1x M4 x40mm bolt

1x M4 nut

2X M4 washer

1X M6 x20mm bolt (M5 for the spring update)

1X M6 nut (M5 for the spring update & lock nut)

2X M8 washers

1x M8 bolt for the driver gear. See picture for the dimensions

1x Filament driver gear

3X bearing 608Z

1X Nema 17 stepper motor

(1X spring for the update)

Comments