Prints (0)

-

No Prints Yet

Be the first to upload a Print for this Design!

Description

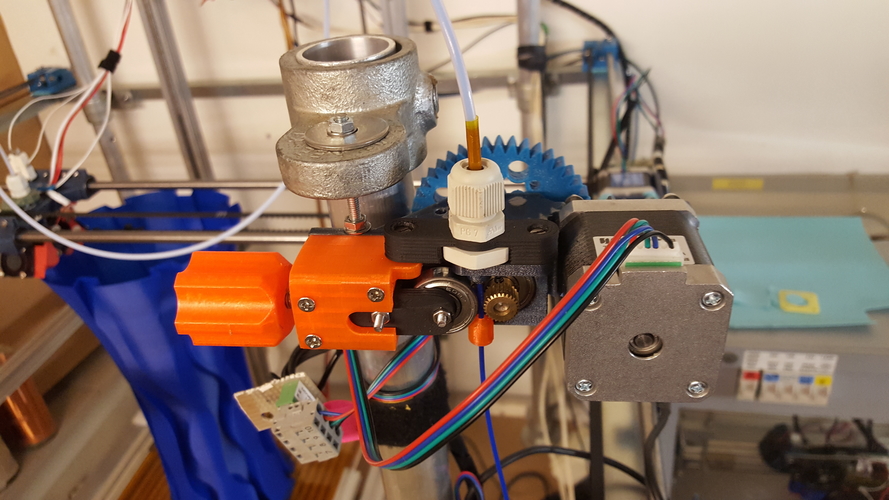

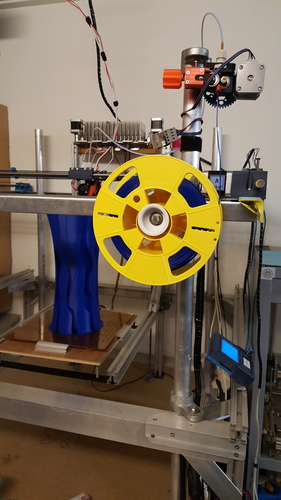

I wanted to make a new Extruder for an printer that I changed to an “bowden setup”.

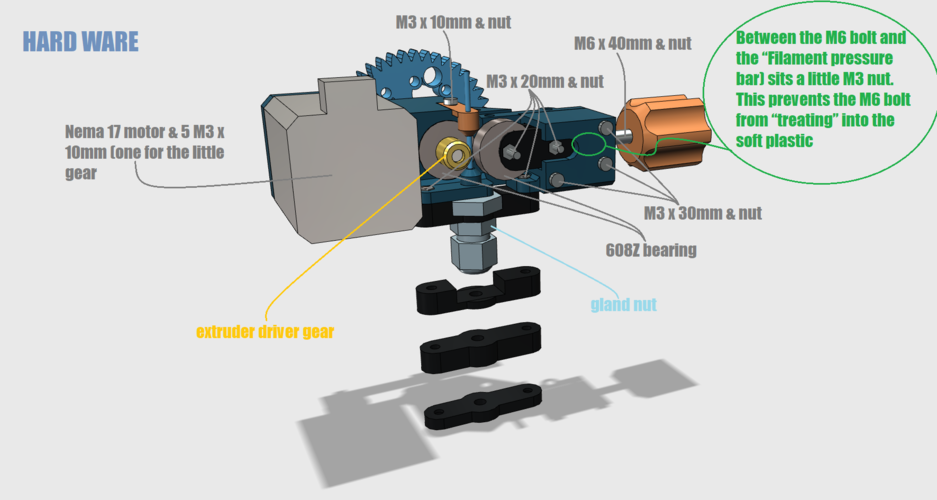

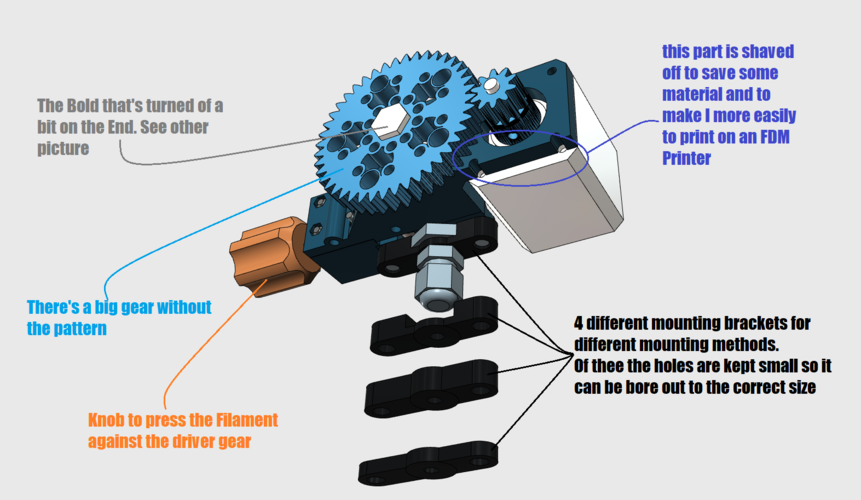

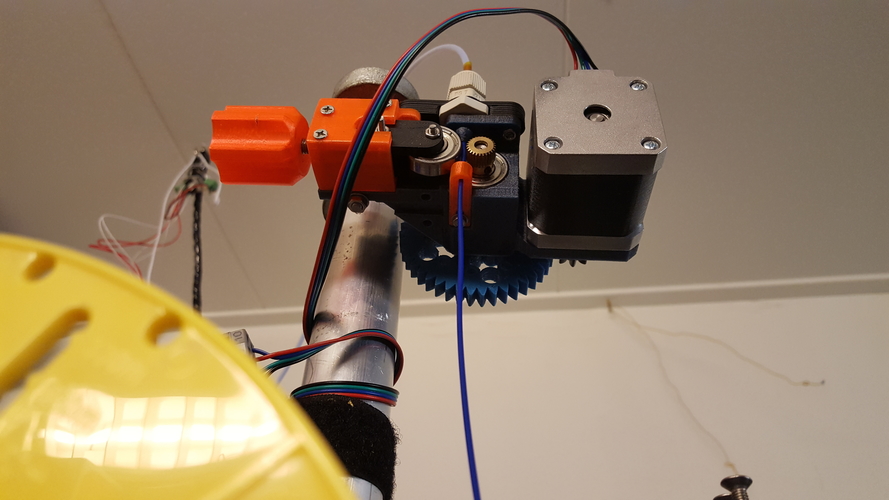

My aim was to make it simple, strong and that the filament could be pressed super hard against the driver gear. Filament can be guided with a adjustable guide. For now I kept the gland nut, but included parts that can be adjusted for regular Teflon tube holders. On the printer on the pictures the gland nut works really well. This extruder en tube setup has made the print test of 20 hours. But on another printer of mine the gland nut works not so good. It's because that one prints with much higher speeds (60mm/s and higher) and than the gland nut does not hold so good anymore. I found that it does help to put Katon tape one the tube :-) I am still experimenting with other tube holder methods :-)

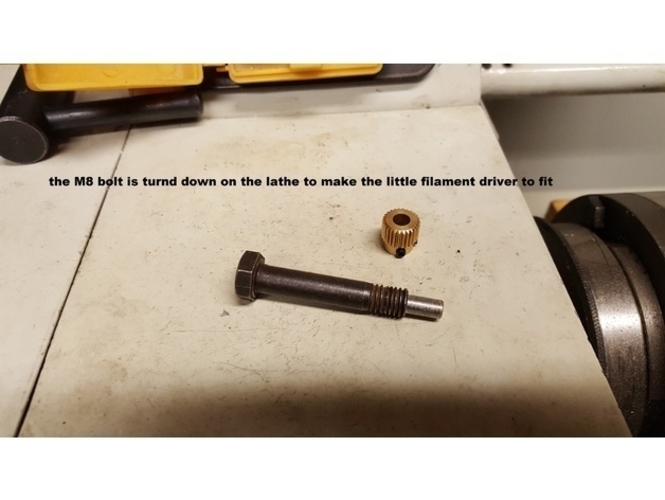

The little filament driver (11mm diameter) is mounted on an M8x50mm bolt I had lying around. On the lathe I turned the end of this M8 bolt down to 5mm so the driver can be mounted on it. See pictures

The model is made for 1,75mm Filament . For 2,85mm & 3mm Filament the holes need to bored out to the correct size.

small gear has 10 teeth and the big gear has 43 teeth

If you have any questions feel free to ask

****************************************************************************************************************************************

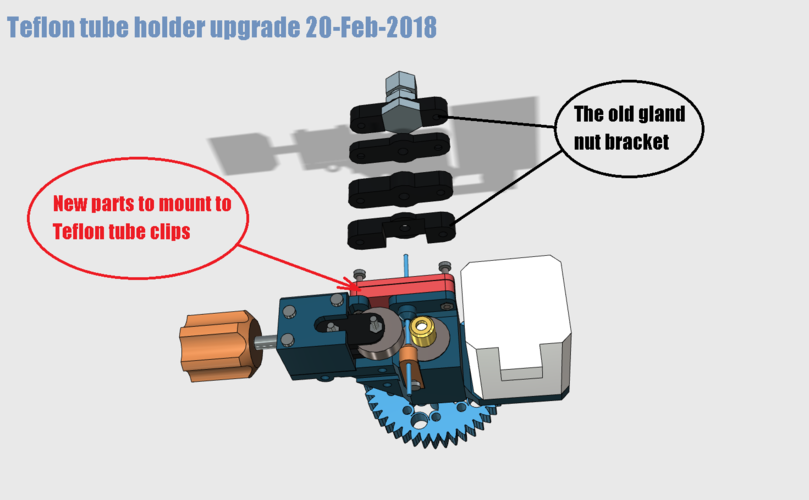

Teflon tube holder upgrade FEB-22-2018

This upgrade is about replacing the gland nut for tube holder clips. See pictures

Experimenting with these clips I can to the understanding that the diameter of the hole where the clip is placed in is very important. Because not all Teflon tubes are the same size the diameter of this hole can be different. The Teflon tubing I have is between 3 – 4 mm. So for me it works best that to bore out the hole with a 6.5mm. But I recommend to begin with 6mm. If that is too tight, bore 6.5mm and so on.

****************************************************************************************************************************************

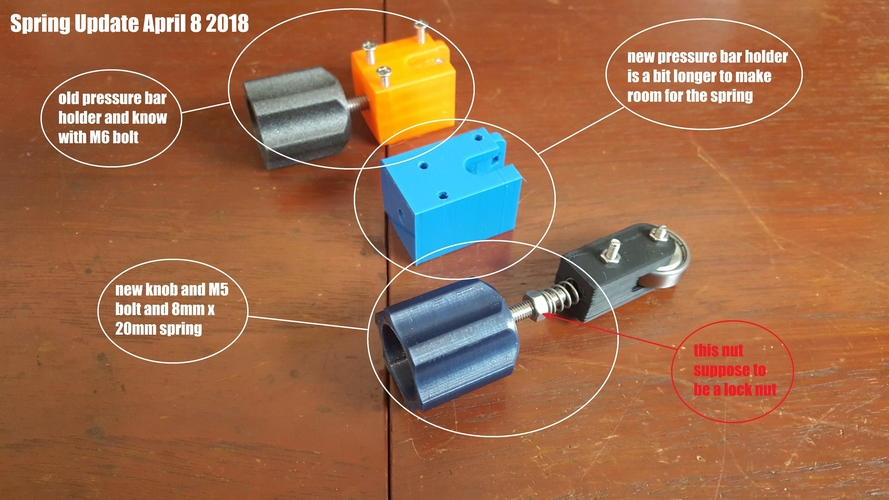

April 8 2018 Spring Update

After using this extruder with great success without a spring, I did encounter problems with a specific filament. Turns out this filament wire was not equally round on its length. It resulted in extruder failures because the filament bar didn't flex with the filament. So when it got to a part of the filament that was slightly thinner. The filament slipped on the driver gear. So I decided to incorporate a spring. Yes I know, I should done this from the beginning, but at the time I wanted to make this extruder as simple as possible. Now I know a spring makes it more reliable :-). Also the spring makes adjusting the pressure on the filament a bit less critical.

Please see additional picture.

* new pressure bar holder is a bit longer to make room for the spring

* new knob and M5 bolt and 8mm x 20mm spring (beware, the old bolt was an M6! But it took to much space)

-

pressure bar modified for the spring

Comments