Prints (0)

-

No Prints Yet

Be the first to upload a Print for this Design!

Description

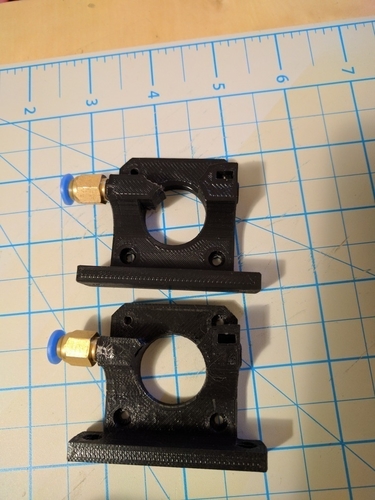

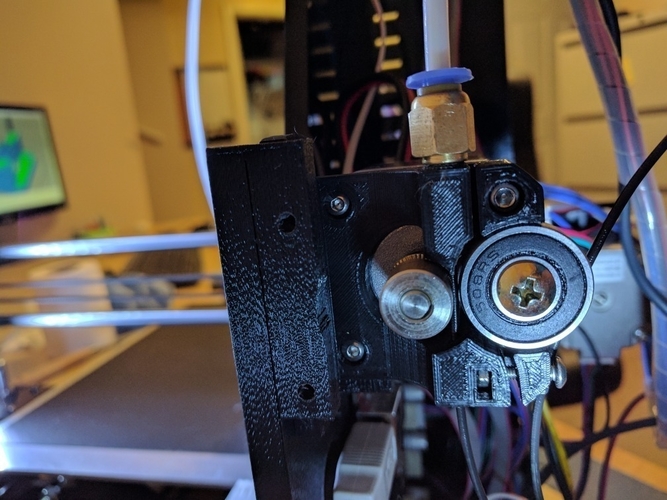

Summary All Original credit goes to tech2c. Heres why i did this. I was slightly under extruding. Different filaments gave me different results when calibrating my E steps. So,i noticed that the gap between the mk7 drive gear and the mount was large. So upon reading more into it, it should be smaller. Also this would also help when using flexible materials. So i decided to extend the mount closer to the drive gear. Now my extrusion is perfect. I suspect the filament bent some previously. **This was my case and may not be yours. Just sharing for others that may need it. For more info, go to the original thing. Print Settings Printer: Hictop Prusa i3 Rafts: No Supports: No Resolution: 0.12 Infill: 50% Notes: I printed at 0.12 and 3 perimeters for a strong part. You can obviously print at larger layer height and maybe less infill. Post-Printing use razor/file etc, to ensure the filament path is smooth and unobstructed

Comments