Prints (0)

-

No Prints Yet

Be the first to upload a Print for this Design!

Description

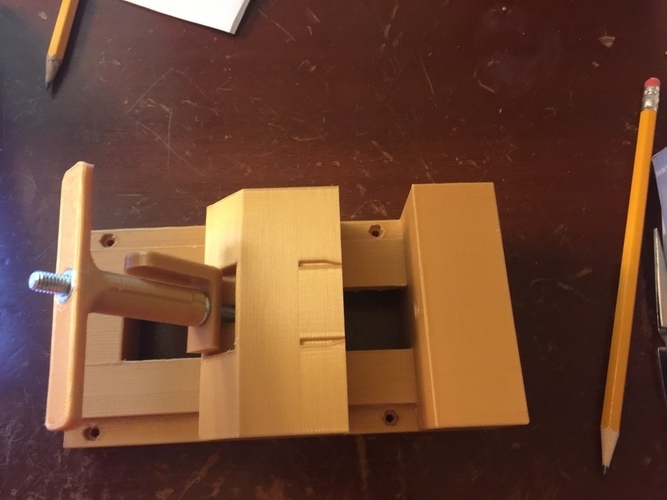

Summary I loved the design of the Original Screwless vise from RhinoAus, however, I searched High and low and I couldn't find a 95 millimeter m5 Bolt. So I just modified the parts in TinkerCad. Without the time I took to test the parts for correct sizing, it took about 15 hours to print this Whole vise. To print just these replacement parts, it took about 6 1/2 hours. Print Settings Printer Brand: Robo 3D Printer: R1 ABS + PLA Model Rafts: Yes Supports: Yes Resolution: .2 Infill: 10% Notes: I used support just for the base overhangs. Your printer should be able to handle the supports within the model. AVOID MY MISTAKE: I used only 2 perimeters in the main base of the vise, this lead to softness in the stationary side of the clamp. (as seen in the last photo at the top of the page.) Try to use 4 perimeters or more if you feel you need to. Post-Printing Sanding and fitting. The top base and the bottom base needed serious sanding to run smoothly enough. I used some tube-lube just to make sure it runs smoothly enough for comfortable and quick use. The Pin shouldn't have a tight fit. It doesn't really need it. Now, I purposefully resized the handle to be an extremely tight fit so that the nut wouldn't come loose. Don't be afraid to be violent to get it into its spot. Or, you can just lightly push it in, and let the actual forces of clamping your first object push it into place like I did. How I Designed This I just used TinkerCad to subtract larger hex, and round holes in the parts that required refitting.

Comments