Prints (2)

Description

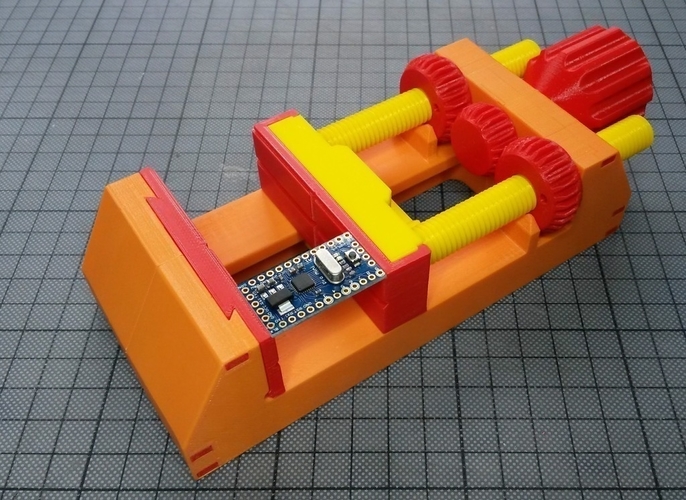

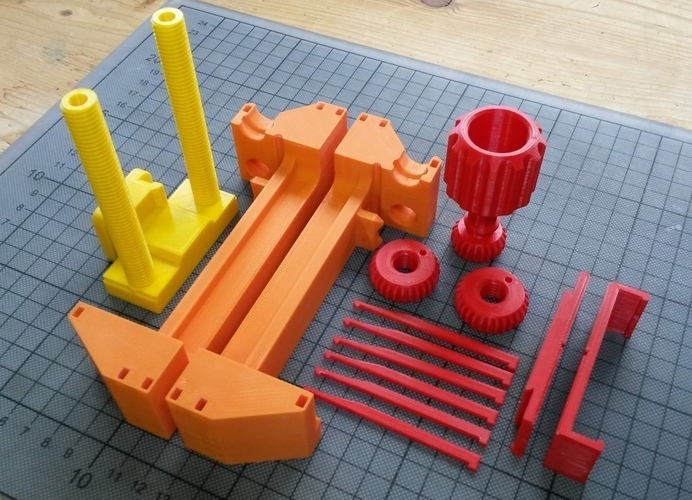

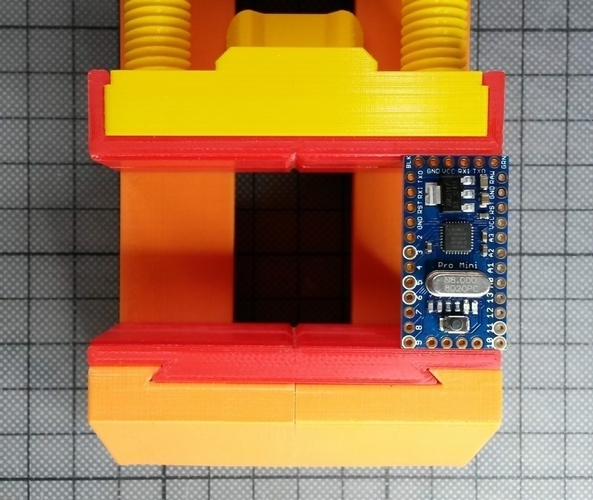

Summary This is a quite robust 3d-printable machine vise. It's 100% 3d-printed - no screw or other piece of hardware is needed to hold the individual pieces together. Pieces clip and snap together. It's a demonstration that it is very important to consider forces and material properties already when designing a mechanical object. Hints about proper design are presented in my video: https://youtu.be/mziT7KV-fRI The video also includes explanations how to assemble this vise. For 3d-printing it's recommended to print 3 shell layers. 35% infill is sufficient. All the forces for clamping a workpiece are only active at the outer surface - more infill doesn't make the vise more robust. Layer height is 0.15 mm (maybe screws are better printed with 0.1mm layers). No support material needed. Printed with 0.4 mm nozzle. Designed with Fusion 360: http://a360.co/2juhSUG

Standards

NGSS

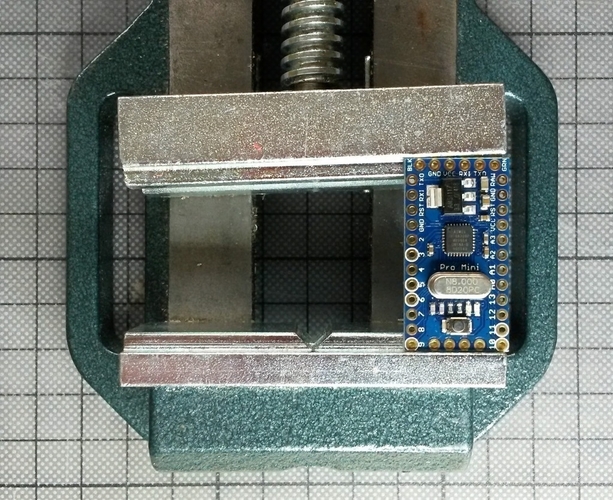

Overview and Background Very often people just try to 3d-print common mechanical objects. But the traditional shape of these objects is often not 3d-printable, and if an object was successfully printed, it maybe does not work, or it is not strong enough. For mechanical objects it is therefore required to adapt the design depending on its future use. If you're familiar with some CAD-tool, and if your creating designs for 3d-printing. I recommend to think about the special material properties of 3d-printed parts. Lesson Plan and Activity Actually I recommend to watch my video on YouTube. With this knowledge you will be able to design better 3d-printable mechanical objects: c-clamp, pliers, stands, geared-transmission, camera-mounts, ... Materials Needed A spool of PLA, or PETG, a 3d-printer, some CAD-Tool (Fusion 360, or Tinkercad, ...)

Comments