Prints (0)

-

No Prints Yet

Be the first to upload a Print for this Design!

Description

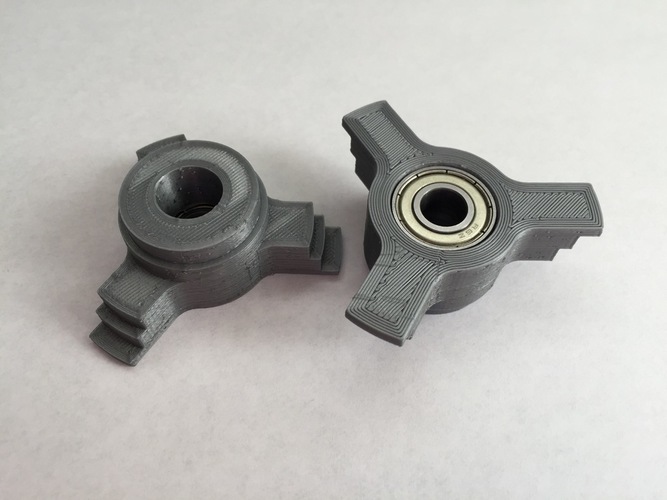

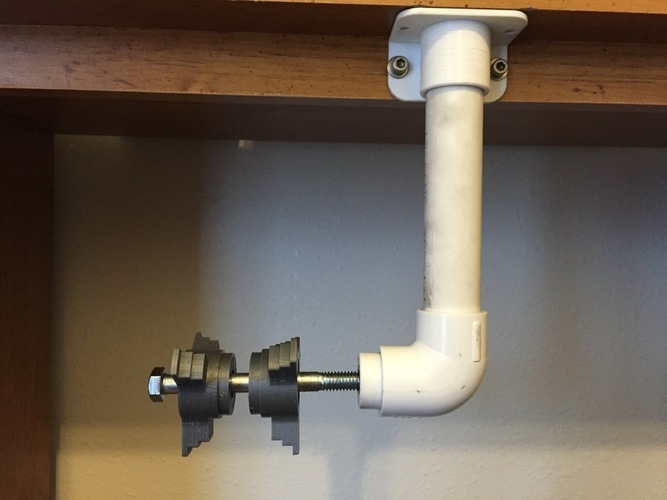

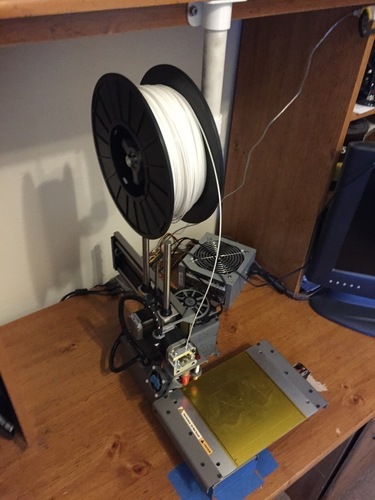

Summary ... I give you the Tri-Adapter Axle. I started by measuring the inside diameter of the spools that I had. I came up with 4 common sizes, all included in my design. I haven't found a spool (yet) that doesn't work. I used a 3D printed angle bracket for PVC that I made and some PVC fittings to mount it above my printer. With 3/8" ID bore bearings: https://www.thebigbearingstore.com/r6-2rs-r6-zz-radial-ball-bearing-3-8-bore/ that pop into the Tri-Adapter body, the whole thing easily screws into a 3/8" coupling nut I mounted in an adapter I also printed that presses into the PVC fittings, all freely spinning on a common 3/8" bolt as an axle. I ended up getting two different length bolts for different width spools, but one long bolt could work for all spools. I hope it serves you well - ENJOY! Print Settings Printer Brand: Printrbot Printer: Simple Silver Rafts: No Supports: Yes Resolution: 0.2-0.3 mm, you choose. Infill: Yes, I use 30-50% Notes: Use your favorite settings and slicer for this part, it is pretty forgiving and should function properly even if it prints rough or ugly. I usually try to avoid supports to keep my stress levels at a minimum, but the bearing housing benefits from the support here. I included my SolidEdge .par (part) file if anyone would like to improve the design, should open in SolidWorks. I used MatterControl ( http://www.mattercontrol.com/ ) to slice and Gcode my STL. I did this because it lets you set the distance that the support is offset from the part, and I really like this feature as I think it improves the removability of the support material. The support material inside the bearing housing popped right out in one piece cleanly. I tried Repetier ( https://www.repetier.com/ ) which I usually use, but didn't like how the support removed leaving the bearing housing rough and required a lot of clean-up. I did the Tri, or three legged adapter to reduce print time and material. In the end, I really like the simplicity of it, that it is small and that it works smoothly. MatterControl also has a nice feature that allows "Support Everywhere". It doesn't actually support everywhere, but this is how it is described in the software: "Generates support material starting on top of internal surfaces. If unchecked support will only generate starting on the bed." I really like this feature. Post-Printing Remove support material... pop in some bearings... DONE. How I Designed This I tried other "spool holders", but they all hang-up or bind sooner or later. Other "rollers" require filament guides and occupy work surface space. I wanted a spool holder that was out of the way, didn't clutter up my work space and provided smooth distribution of filament preferably with bearings that I could change out when needed for a variety of spool sizes. When I used other "holders", often I would have to tighten my filament feeder bearing so tight it would smash and oblong the filament so it wouldn't fit through the extruder and would jam up. This ruins a lot of filament quickly. Other "rollers" need guides to get the filament up and over everything to get the filament from the spool to the extruder because they sit on the work surface. Each of these "guides" can also jam up the filament or require bearings themself. It seemed that it could all be done easier...

Comments