Prints (0)

-

No Prints Yet

Be the first to upload a Print for this Design!

Description

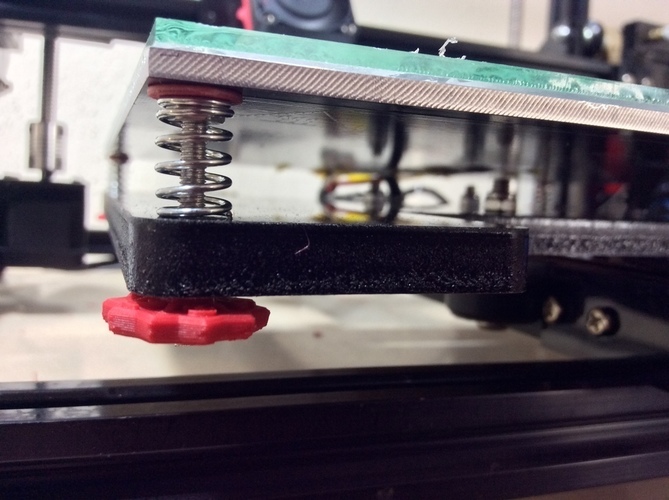

Summary Small 18mm thumbwheels from manually adjusting beds on assorted derivative i3 kit printers. Replaces smaller metal thumbscrew nuts and wing nuts but should not bump into anything. An M3 screw has a 0,.5mm pitch when means a full turned of a bed leveling nut moved the bed 0.5mm. Two turns would be a full millimeter. The thumbwheel I designed has 10 points on it so every point is 0.05mm height change. Two points would move that corner of the bed up or down 0.1 mm. I created another thumbwheel design that is too big for some of my newer i3 kits. This thumbwheel works well with new Tronxy X3, as well as the Zonestar P802M, and a couple other i3 kits that have. Print Settings Printer: Tronxy X3 Supports: No Resolution: 0.12mm - 0.16mm Infill: 20% Notes: Has a built in support ring that you should be able to push out with a 2.5mm hex wrench. A M3 nut should press fit into it. 3 shells. Post-Printing Use a 2.5mm hex wrench to pop out the support ring. Press in an M3 nut. How I Designed This I used my drug of choice, Onshape. Started the design on my iPad, then refined in on my iMac.

Comments