Prints (0)

-

No Prints Yet

Be the first to upload a Print for this Design!

Description

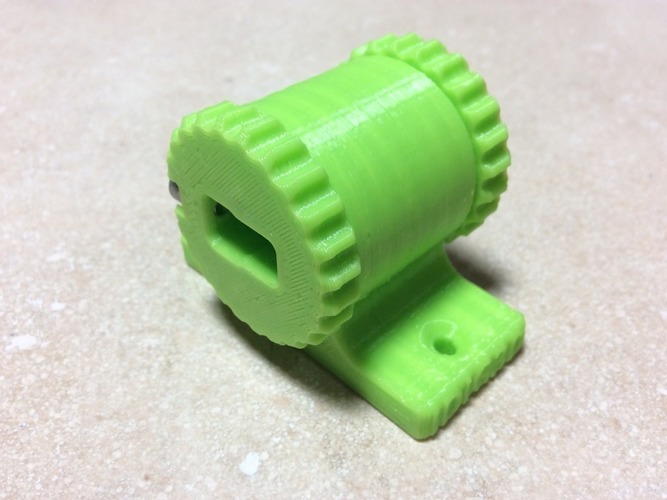

After showing a buddy my Solder Fingers, he wanted something to hold a Deans connector for soldering. So I thought this up, and way over engineered, but a fun little challenge. The thumbwheels rotate and click in on 90º. You can insert a mating connector and tighten the set screw to hold it so it can hold the connector and act as a bit of a heatsink. Screw holes to mount to bench or snap in a magnet. Printed best in something more flexible than standard PLA--high-temp PLA, ABS, PETG, or ASA. Needs: 4 M3x10 screws for dial assembly 2 M3x6 screws for set screws to hold mated connectors 12mmx3mm magnet for base https://youtu.be/tqZjS9RRJLIPr...

Printer: i300Pro, Rafts: No, Supports: No, Resolution: 0.2mm, Infill: 10%. Notes: 3 perimeters. Use something less brittle than standard PLA.

Start two M3x10 screws into 4-pointed catch. Stack on top of clicker and screw in. Stack on top of dial and tighten screws, but not all the way. The clicker should be ever so slightly loose. Repeat for other side. Hold assembled dial in hand, rotate 45º and align with base. get started and the force in. Rubber mallet may help here. Should be tight fit. The clicker point should snap into place. Rotate both ways to smooth it out a bit. A bit of teflon powder would help here. Snap in other side. Line up 12mm (OD) x 3mm magnet in hole in bottom of base over hard surface. Push down to seat it. Should not be loose. If so, glue it.

Used my favorite stimulate, Onshape, to design this.

Comments