Prints (0)

-

No Prints Yet

Be the first to upload a Print for this Design!

Description

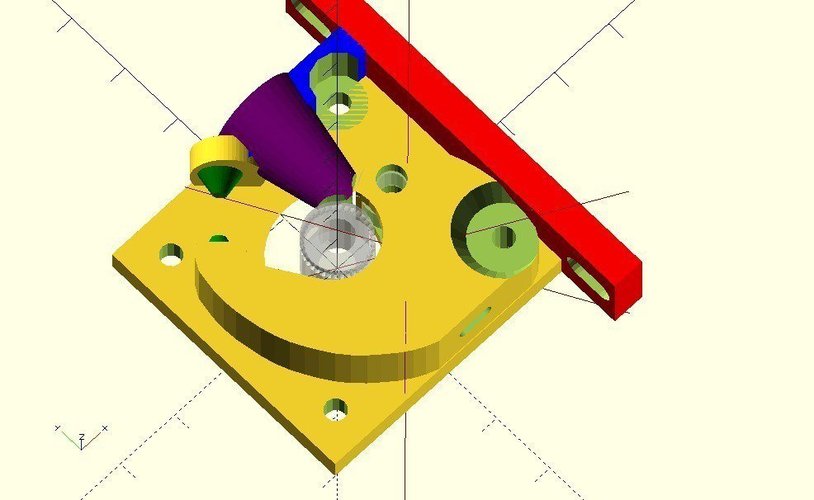

Summary There are a lot of good struder designs but I couldn't find anything right for me. My requirements were: 9mm x 4mm x 4mm thick brushless motor bearing. (http://hobbyking.com/hobbyking/store/__10201__HK_500GT_Ball_Bearing_9_x_4_x_4mm_Align_part_H60103_.html ) 10mm fine pitch bowden clamp for tube for 4mm OD tube. ( http://www.robotdigg.com/product/348/Heavy-duty+push-fit+bowden+connector+4-01 ) Long direct drive 400 step per rev low voltage Nema 17. ( http://www.omc-stepperonline.com/9deg-nema-17-bipolar-stepper-44ncm623ozin-17hm191684s-p-12.html ) side mounted. So I mucked around this last weekend, set it printing late at night and it came out perfectly first time. I love it! :-) Clearances around the 1,75mm filament along the compression path are purposefully minimised to allow for printing Ninjaflex etc. Be sure to insert a stiff spring between the base nipple and the swing arm nipple to force the roller and filament against the pinch roller.This uses a 10mm diameter pinch roller, don't tighten the grub screw until you have some filament fed through the cavities to hold the pinch roller in place. Note that the swing arm has some bridge support built in which will have to be removed before the bearing is inserted. Also wind down your motor current a bit before fitting the linked stepper motor. The extra length gives it great torque. Use 1 x m3 x 16mmwith an m4 nut for a washer, 3 x m3 x 8mm and 1 x m4 x 10 bolt for the bearing. The spring can be wound from piano wire if you can't find a ready made one. My spring has an outside diameter of 10mm, a wire diameter of 1.24mm and an uncompressed length of about 19mm.

Comments