Prints (0)

-

No Prints Yet

Be the first to upload a Print for this Design!

Description

Summary This is my entry for the #CatchTheWind contest. This is a windmill that has a 11 to 1 gear reduction to enable you to do things that you just can't do without gearing. Things like pump water, power complicated whirligigs with many moving parts, or anything else you can imagine! This one will power a rock tumbler when it is finished. My wife doesn't want a rock tumbler in the house because of the noise so this will have a home in the corner of the yard closest to my most annoying neighbor. Please take the time to Like this for the contest.

Here is a video of it

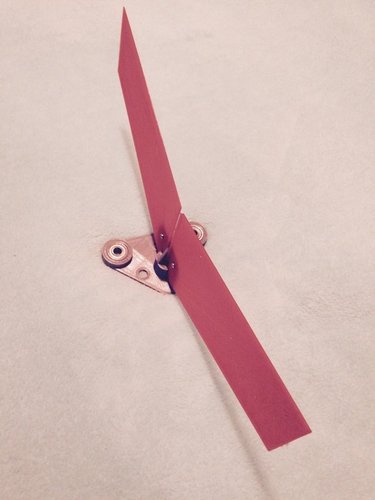

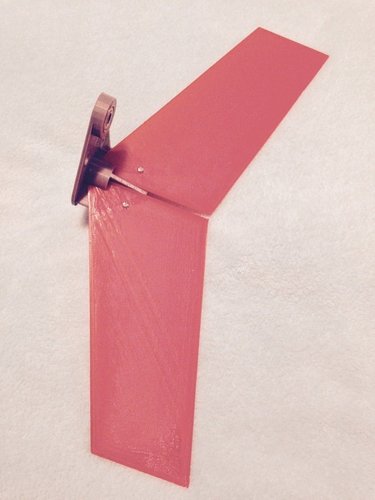

Instructions All parts print flat without support. Stack the blade parts on threaded rod and tighten them together. They align themselves and lock into position. 608 skate bearings are used on either side of the gear plates to ensure smooth movement. The rock tumbling grit will simply be various grits of sandpaper cut into small pieces and a cup of water. Start with a coarse 100 grit and finish with a very fine 1000 grit. There is no need to buy the very expensive commercial grits available for rock tumblers. The paper gets pounded into nothing by the rocks and the grit ends up in solution to polish the rocks. Enjoy the build! Final assembly complete. Pardon the mix of measurements, I get imperial hardware cheap but I think in metric.

- 1 threaded 5/16th inch rod 410mm long (blade drive)

- 1 threaded 5/16th inch rod 314 mm long (tumbler drive)

- 2 threaded 5/16th inch rods 212mm long (bottom supports)

- (vary rod length for taller or shorter jar)

- 1 jar 150mm high 90 mm diameter (spaghetti sauce)

- 1 5/16 inch bolt 50 mm long (or a section of rod for idler gear)

- 2 large washers 36mm in diameter or larger to keep jar centered

- 1 bolt 5/16 for tumble jar 55.5 mm overall length

- 2 nuts and bolts 2mm for fins (anything will work drill for what you got)

- 2 rubber grommets or sections of rubber tube forced onto drive rod.

- 16 skate bearings (608)

- 26 5/16 inch nuts

- 14 small washers

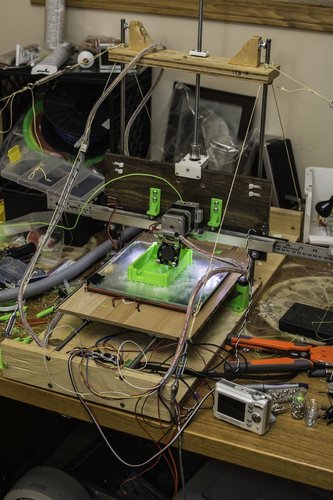

This was modeled in Sketchup. The files were converted to STL format using the SketchUp STL plugin. The files were checked for manifold errors using the Solid Inspector plugin. And the files were cleaned with the Cleanup plugin during construction. All parts were printed on my RepStrap Monkey S#t Fight and will print on any 200 200 mm bed. I used PLA with 3 shells and %40 rectilinear infill for all parts.

Assemble as shown in the pictures and mount on a pivot using the frame pivot tube. A glass marble on top of a stick makes a decent pivot. Mount in a windy location and enjoy your shiny new rocks in a couple weeks!

Comments