Prints (0)

-

No Prints Yet

Be the first to upload a Print for this Design!

Description

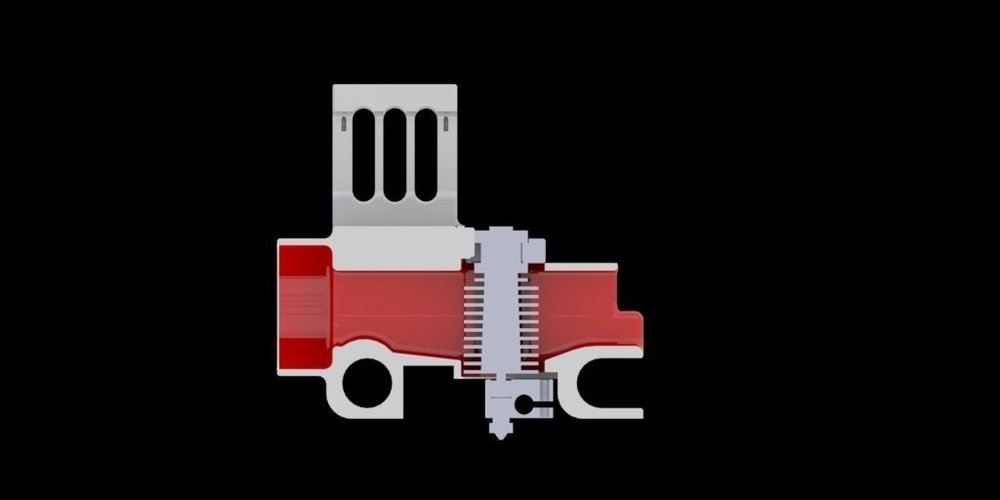

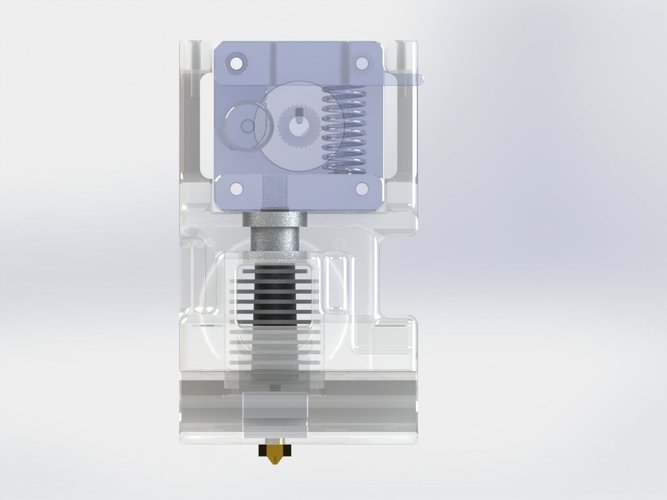

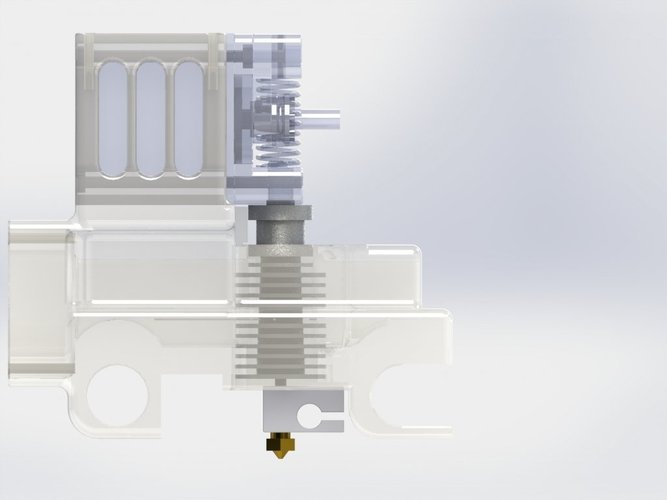

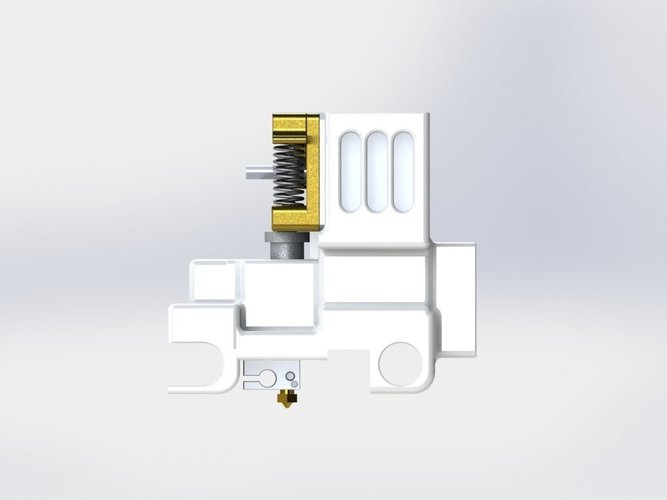

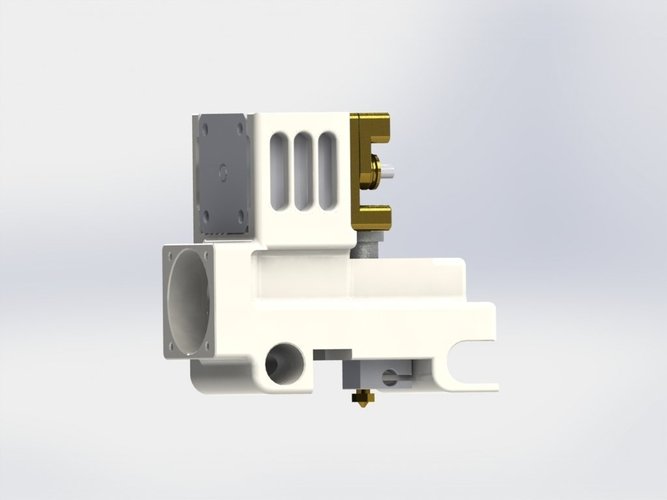

If you have trouble purchasing my designs, send a message to me at https://www.facebook.com/CallEnterprises/ and please feel free to donate through Paypal to [email protected] and I will keep the designs coming. Allows Da Vinci 1 users to adapt a "Genuine" E3D V6 hotend and MK8 extruder in to a Da Vinci 1 3D printer UPDATE 3/22/15 There are lack of space issues with the Teflon tube and fitting that inserts into the top of the hot end. See the instructions for details. I have fully machined hardened X-axis shafts available

UPDATE 3/22/15 Modified the carriage to accept a retaining bracket for the hot end. Also added a retaining bracket for the hot end.

UPDATE 3/21/15 8:50pm pst Replaced the carriage file with a file with a better cooling duct. Instructions Hotend Teflon tube fitting clearance issue: One solution may be to remove the tubing fitting or cut it off flush with the top of the hotend and insert the Teflon tubing directly into the hotend. Make it stick out of the top of the hotend just enough to be inside the 6mm threads of the MK8. The required Teflon tubing is 4mm OD and the hole in the MK8 is tapped to 6mm. The ID of the threads in the 6mm hole (about 5mm) should be close enough to the OD of the Teflon tube (4mm) to keep the tube centered. If the tube is loose in the threads of the MK8 you could wrap a piece of tape around the tube to get a better fit. This is just a suggestion. Print on the right side for better print results. Depending on how accurate your printer prints holes the bearing holes may need to be drilled or reamed to fit 15mm bearings or 16mm bearings. The bearings holes are drawn at exactly 15mm. Permanently glue the belt grip into the carriage with acetone. Linear roller bearings require the old rods for the brass bearings to be replaced by hardened rods or the roller bearings will destroy the old rods.

Comments