Prints (0)

-

No Prints Yet

Be the first to upload a Print for this Design!

Description

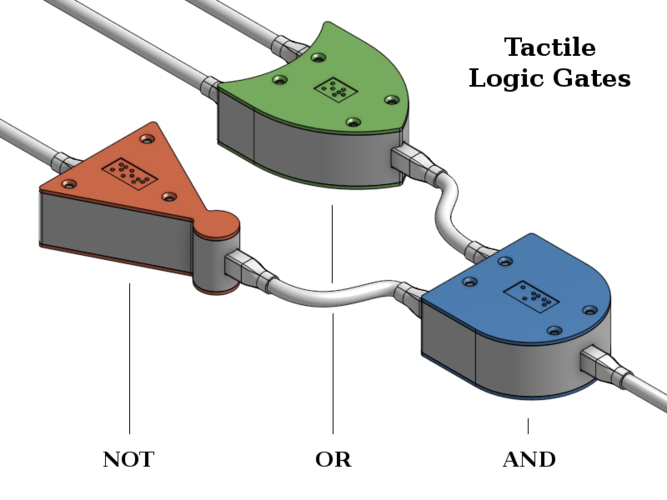

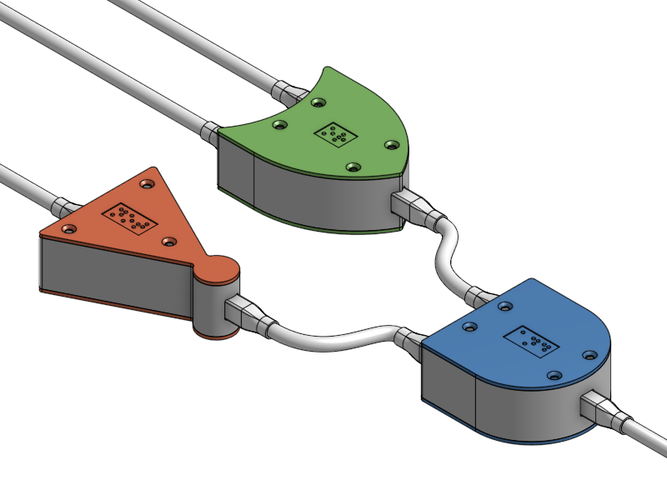

Tactile Logic Gates

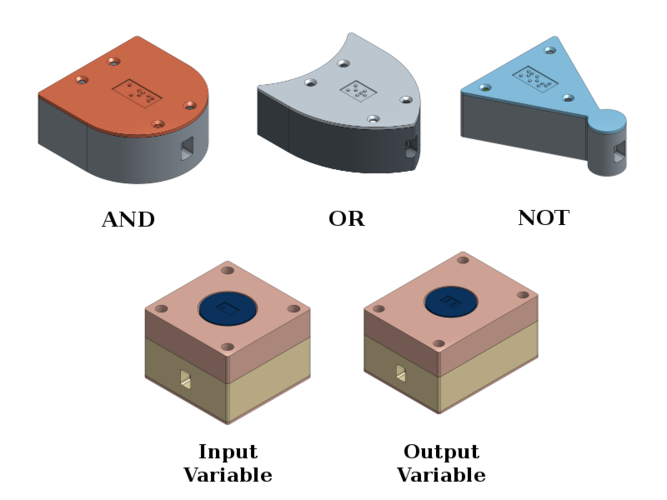

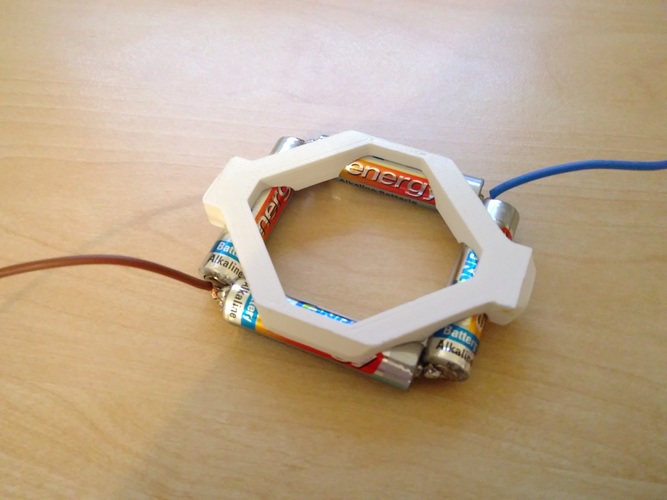

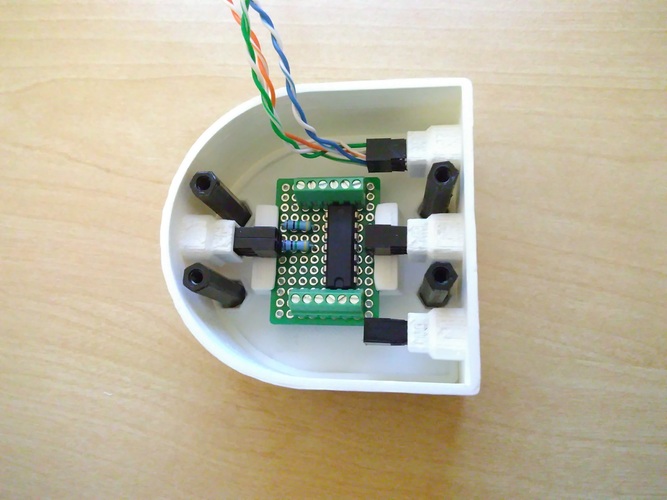

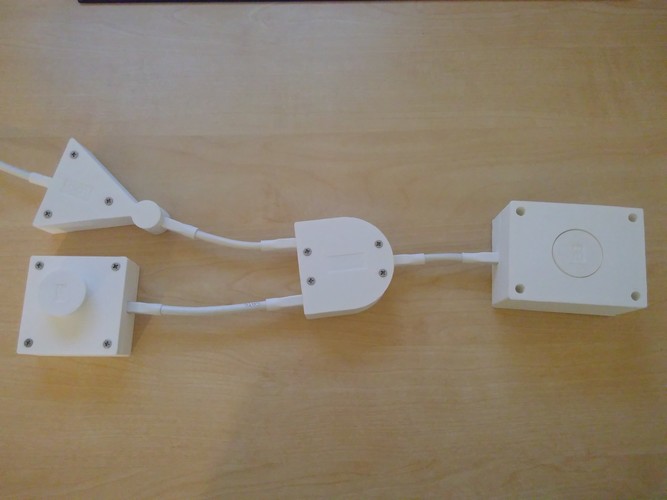

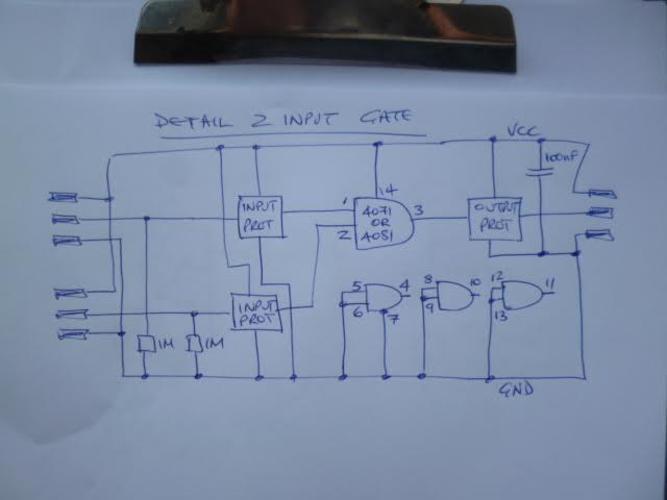

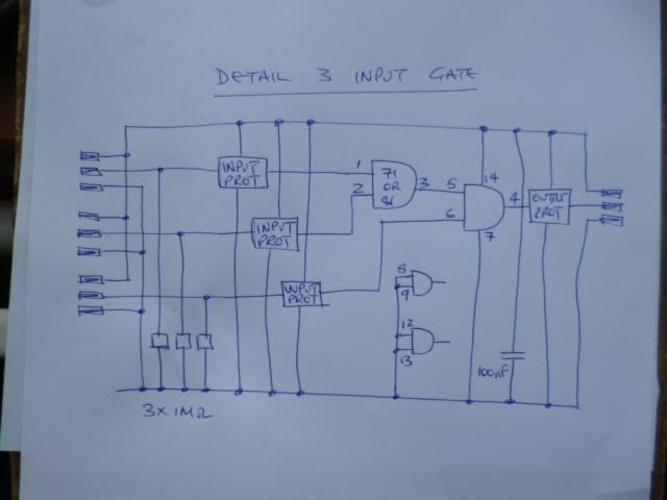

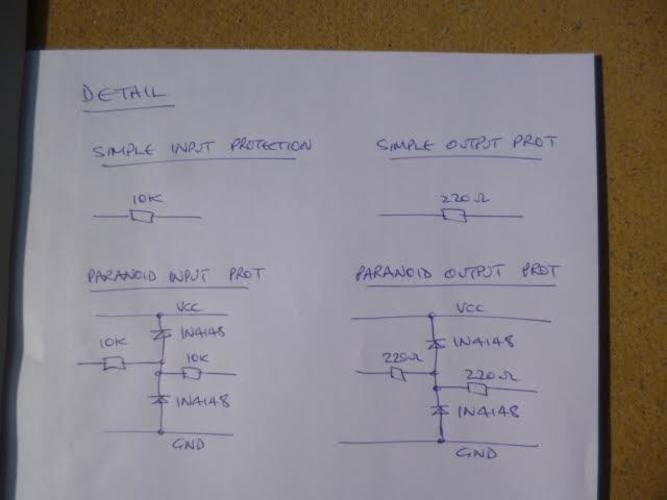

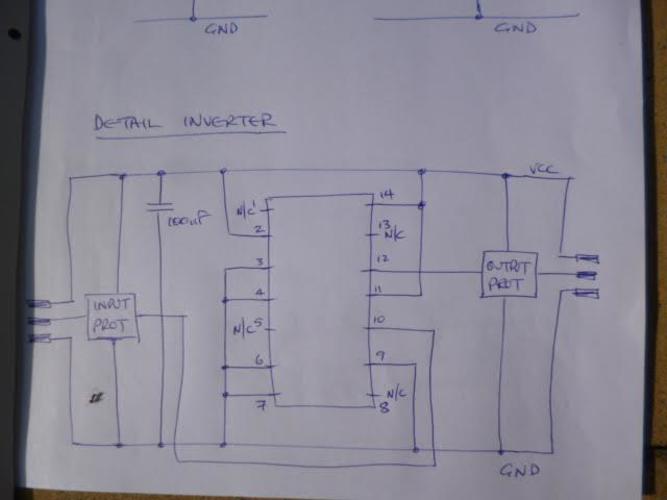

The 5 boxes presented here are a prototype and proof-of-concept for a set of educational toys, specifically designed to teach simple propositional logic and logic circuitry to the visually impaired. They are presented with physical representations of the three basic logic gates (AND, OR, NOT), shaped like their traditional representations in logic circuit diagrams. They actually perform their respective functions and can be plugged together using safe cables to create a working circuit.

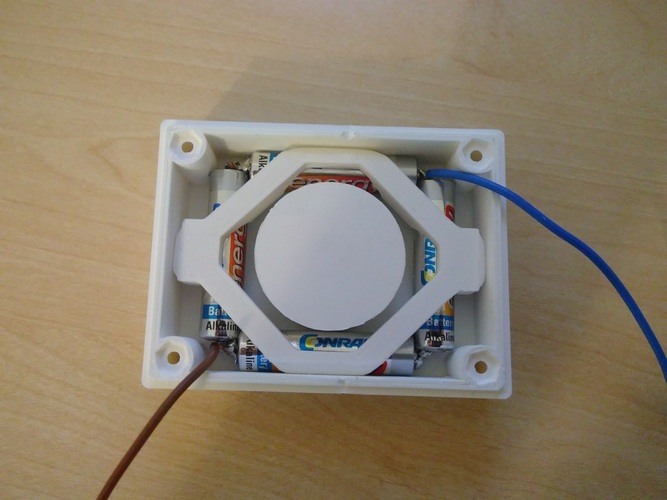

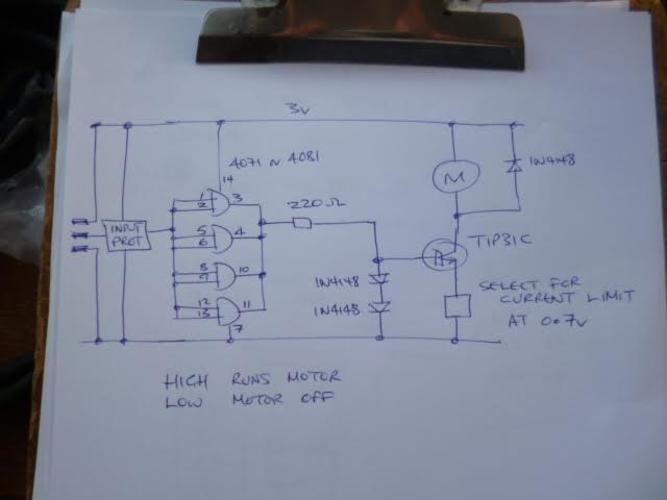

Inputs to this circuit are represented by the Input Box, which has a simple on/off switch to toggle between a TRUE or FALSE input. Outputs are represented by the Output Box, which lifts or lowers a tactile indicator based on the signal.

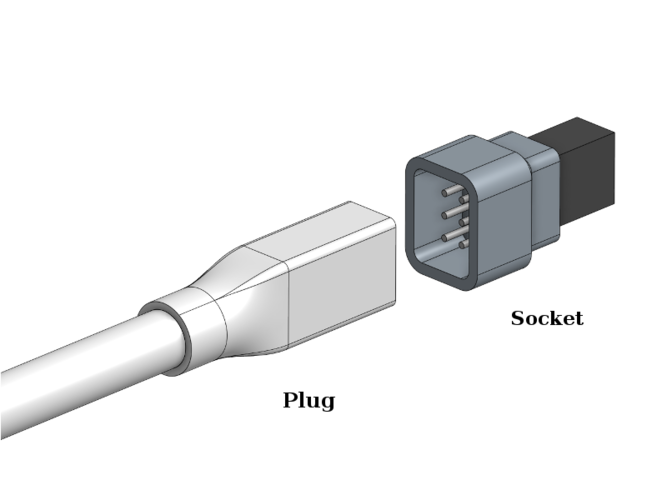

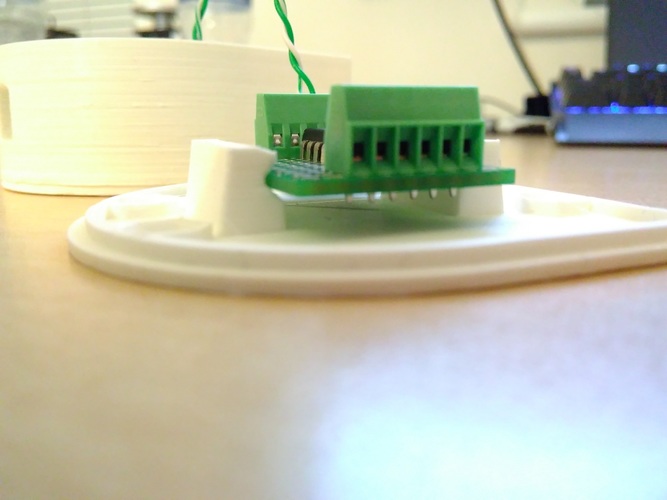

The sockets have 6 pins, but the cables need only 3 cores: power, ground, signal. So the plugs can be inserted in either orientation. (Take that, USB!)

Print Settings

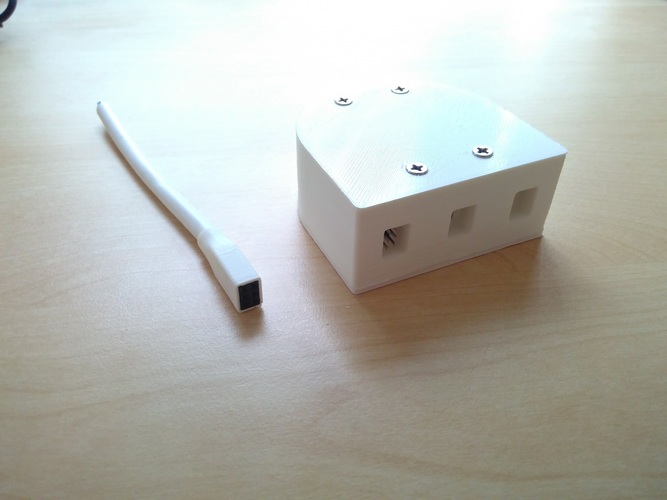

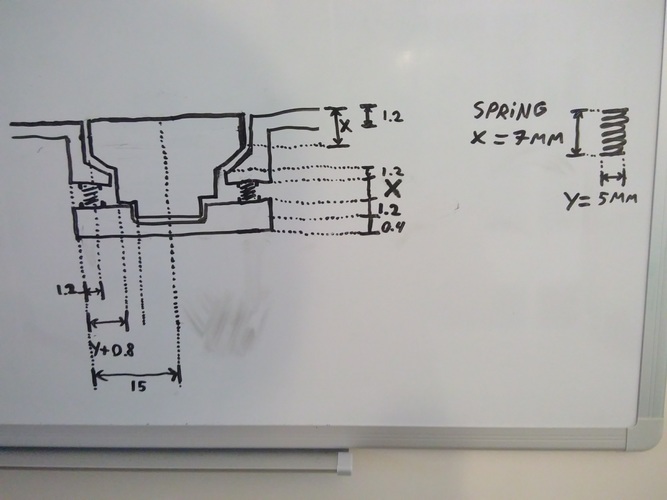

Layer height: I printed all of these with PLA at 0.2mm layer height, but the interlocking parts should be designed with sufficient tolerance to work well with other settings. Do note that the braille text is 0.4mm thick. Dimensions for the braille characters were taken from brailleauthority.org; they recommend 0.48mm, but I wanted to stay a bit closer to standard layer heights.

Extrusion width: I used an extrusion width of 0.42mm. This worked well for me, using Simplify3D, when printing some of the thin walls in these designs. Your mileage may vary.

Support structures: The only parts that require support structures are the various Walls (because of their sockets). The rest should print fine without them. Various overhangs are limited to 45° for your printing convenience. The surfaces containing braille should be printed face down, because the other side has various bits sticking out. The braille cells are inset for that very purpose, and should print fine if you have decent print surface adhesion.

To Do

- A shopping list for the various components required to build the electronic circuits. The prototype uses the components that could be found in a short time-frame, and I will not inflict those particular bad design choices on the world (yet).

- A 3D design for a Fan-Out component, to allow a single output to be duplicated into multiple leads.

- Smaller boxes for all components; these are still kind of big and awkward.

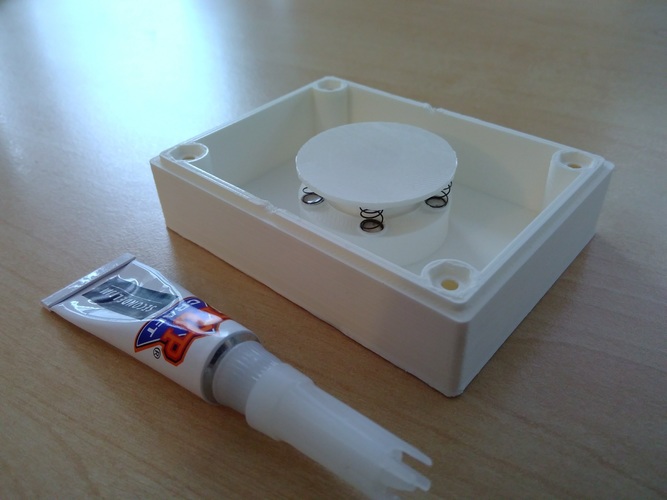

- A more sensible actuator to use in the output-box. It is currently using a simple DC motor that stalls against a barrier (pushing the indicator up). It was all I had to hand, but it is terribly inefficient, and requires those springs to pull the indicator down again. Subsequent versions should make this much easier.

Acknowledgments

Many thanks to Neil Thomas for helping me with the electrical circuit designs (the electrical circuit drawings are his). As a 3D printing enthusiast and software developer, I am a complete rookie when it comes to electronics, and found myself woefully underprepared. I could not have come this far this fast without Neil's help.

Design Process

I designed the 3D parts in OnShape. The original designs are public. Feel free to play around with them!

The attached photos show the various stages of my design process. And here are some videos of my testing the output mechanism:

Comments