Prints (0)

-

No Prints Yet

Be the first to upload a Print for this Design!

Description

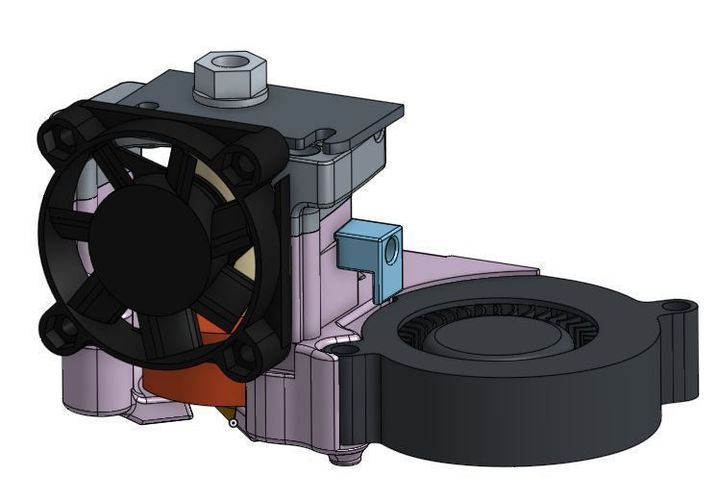

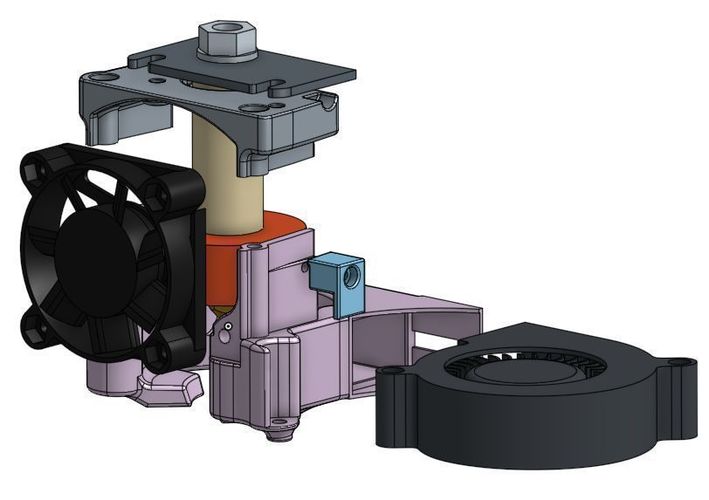

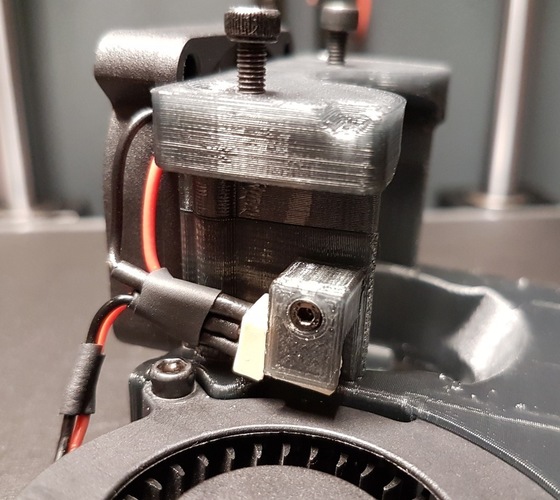

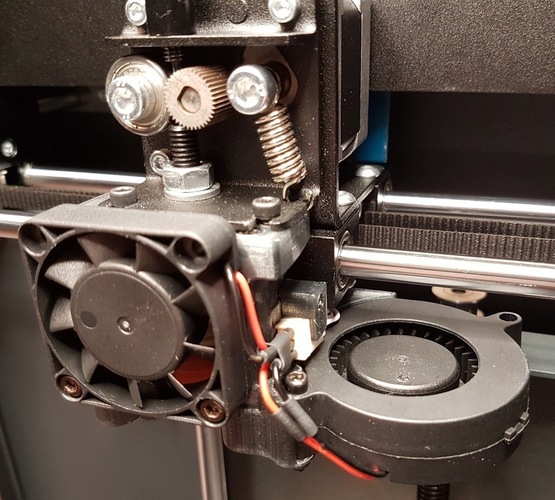

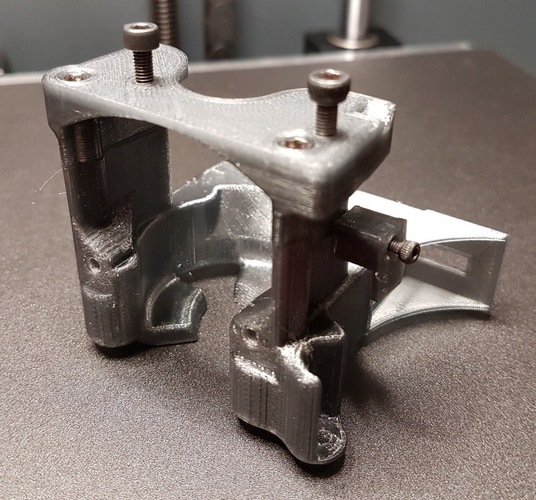

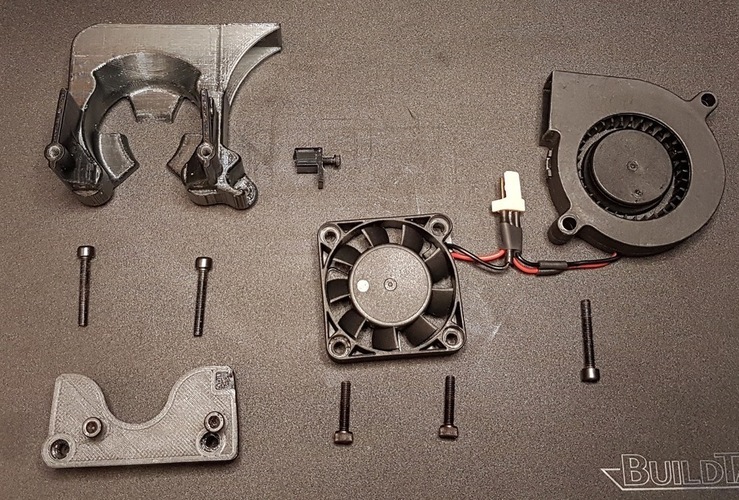

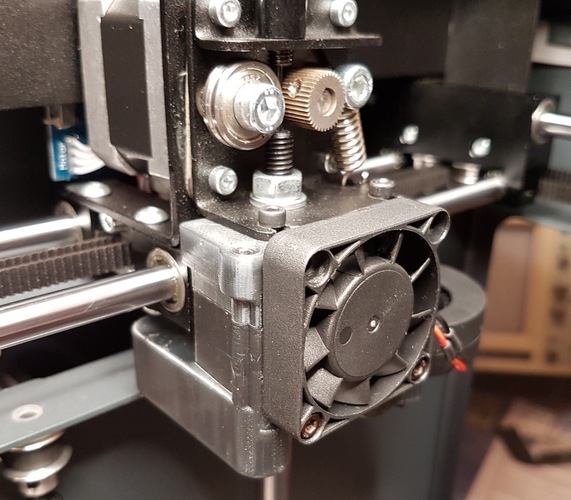

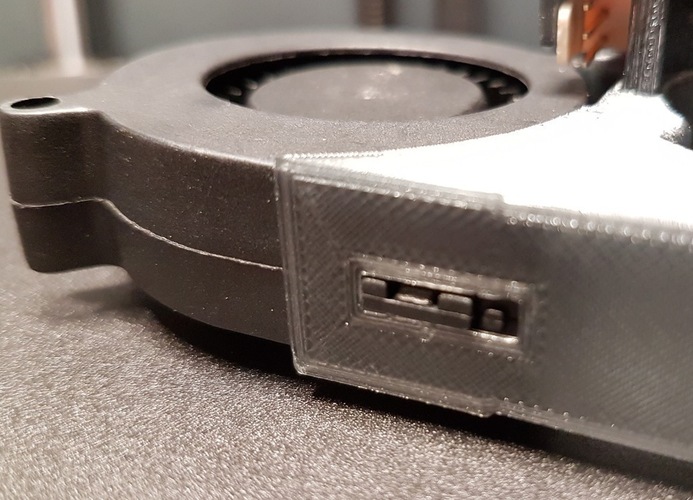

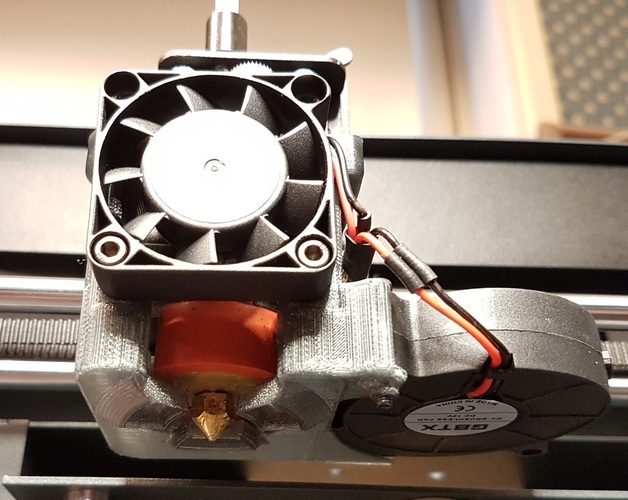

Summary This is a custom print cooling solution for the Craftbot, replacing the stock solution. Instructions Introduction The stock cooling on the Craftbot doesn't really cool well enough right where it is needed. Instead it provides a general flow of air from two angled axial fans, blowing in the direction of the heater block and nozzle. The big problem with creating a custom solution is that there is very little useable space around the extruder when it approaches the x and y limits. The Craftbot is a very compact machine, and while that is very nice for your desktop space, it makes life hard for someone trying to create a custom cooler. This cooler uses a common 5015 blower fan that pressurizes a plenum chamber, from which three nozzles direct the air just where it is needed, close to the nozzle. The flow from the three nozzles is fairly even, providing good cooling from three directions. I have only tested this on my Craftbot 2, but I believe that the Craftbot Plus should be identical. I do not know if it will also fit the original Craftbot. Printing The cooling duct needs to be printed on it's back, and some supports are needed: 1) Inside the cavity, just where the middle nozzle is 2) In the opening for the blower fan, to make sure it doesn't droop 3) Under the two side nozzles 4) Under the vertical walls 5) Where the blower fan screw mount is (can often be skipped, though) Do not go overboard with supports, as it will only make removal difficult. Recommended resolution is 0.2 mm, and it is probably best to use a material which handles the heat (ABS/PETG), as this sits very close to the heater block. The mounting bracket and the connector holder bracket does not need supports, but it may be necessary to clean up the holes a little bit. There are some very thin walls in the duct (0.8 mm), but when assembled, it will be plenty strong enough. Recommended supports for printing Assembling and additional hardware To assemble this, you will need: A 5015 blower fan (like this one: http://www.ebay.com/itm/222278030829), needs to draw less than 0.24 A, but for good efficiency it should be 0.14 A or more. A 40 x 10 mm axial fan (can re-use one of the original fans if needed). If buying a new fan, make sure it has a similar rating to the stock one (0.12 A). M3 socket head screws: 2 x 14 mm (for the extruder fan) 1 x 20 mm (for the blower fan) 2 x 20 mm (for mounting the bracket and the duct together) 2 x 10 mm (for mounting the assembled cooler to the printer) One M2 15 mm socket head screw for the connector holder bracket The holes has been sized so that the screw should thread right into the plastic, but I do recommend using a M3 tap to pre-cut the threads. When assembling, first attach the top bracket to the duct itself, using two screws. Then the blower fan should snap right into place, just insert it at an angle, and then rotate and push it into position before inserting the screw to hold it firmly in place. The little tab on the fan should lock into the slot in the cooling duct. The extruder fan is screwed right onto the duct itself, using two screws. I am not going into any details on the electrical part of this, but you will need to do some soldering to connect the fan wires to a suitable male connector to plug into the female connector on the Craftbot. Again, you can of course desolder this from the original cooling, but I'd recommend to keep that as-is, and just buy a new connector or use some pins soldered to the wire ends as a makeshift connector. However, be careful to insulate any bare wire, as short circuiting will blow the driver on the main board. The assembled unit, ready to mount to the printer: Assembled unit Notes This cooler has been designed for the stock hotend, and will most likely not fit if you have a custom hotend on your machine. And as mentioned, the space around the extruder is very sparse, and the clearances when using this cooler is extremely small. After mounting it, please move the extruder around manually to make sure it doesn't touch anything. Here are some images showing just how tight it is on my machine (a Craftbot 2). Almost hitting the bolt heads for the Z-rods Barely any clearance to the right hand side frame lip

Comments