Prints (0)

-

No Prints Yet

Be the first to upload a Print for this Design!

Description

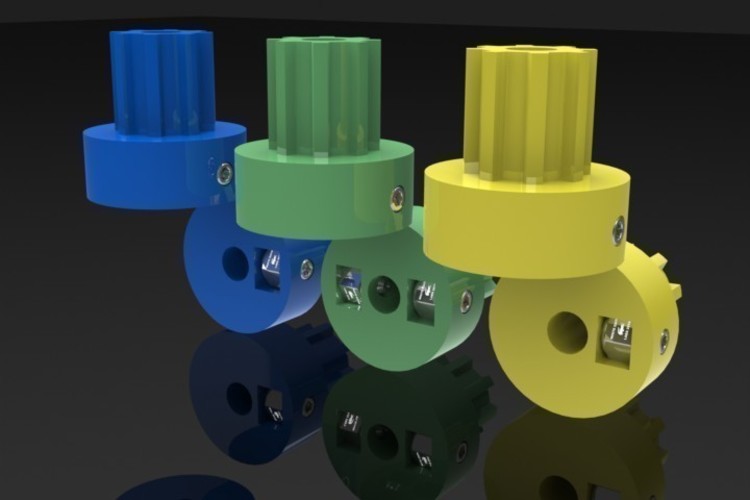

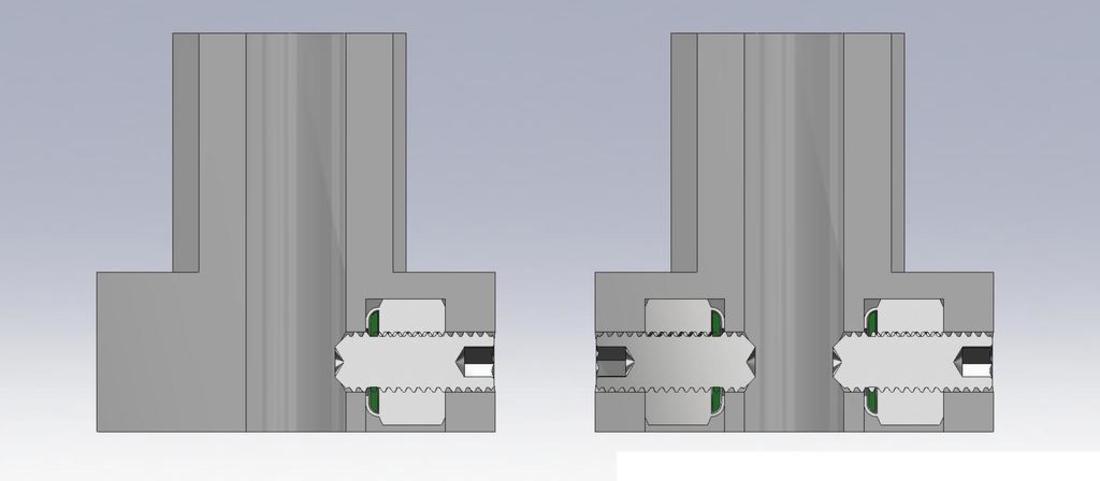

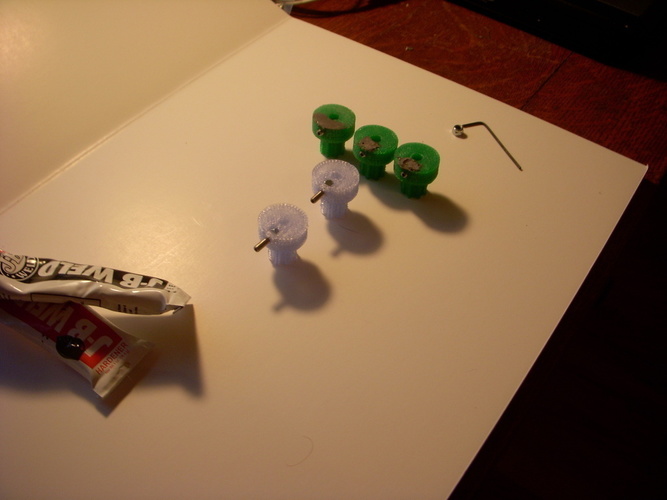

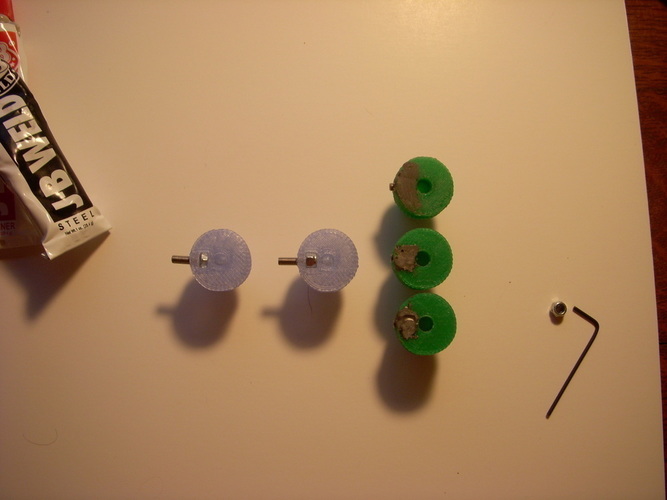

SummaryDerivative Work from Nophead's and Adrian's Pulleys Reason: Set Screw can come loose after long prints Cause Poor print quality. Happens In only My X Pulley, why? Three new Variations to Nophead's Pulley design. Added feature include: 1) Solidworks History Tree 2) Solidworks Assembly File 3) Replaced M3 nut with Nylon Locking Nut (No more Locktight) 4) Less Chance of Screw Slipping out 5) Nut turned at 60 degrees for better holding strength (Not a plan 5.5mm X 2.5mm Rectangular extrusion hole) 6) Direct Replacement for Nopheads Pulley 7) Thee Flavors to choose from A) Single Locknut Pulley B) Double Locknut Pulley ___C) Single Locknut Pulley With overzied Locknut hole (experimental)InstructionsParts needed: 1) Fuller Lock Pulley 2) 3mm locking Nylon Nut (Or 2) [ McMaster-Carr #90576A10] 3) 3mm X 8mm Set Screw (OR 2) [ McMaster-Carr #92015A105] 4) JB WELD (Locktight who needs it?) Assembly: 1)Print Pulley of choose 2) Ream hole to desired dimension (5mm and 3mm respectively) 3) Set Nylon Locking nut into place 4) Screw in Set Screw until reaching Nylon insert 5A)Mix Up JB weld and add to top of screw. Spin Set Screw and if the nut spins add more JB weld so it may cover everything inside (Minus Screw) Let dry for a couple of hours. 5B) Extrude plastic on top of locknut 6) tighten down for trouble free prints

Comments